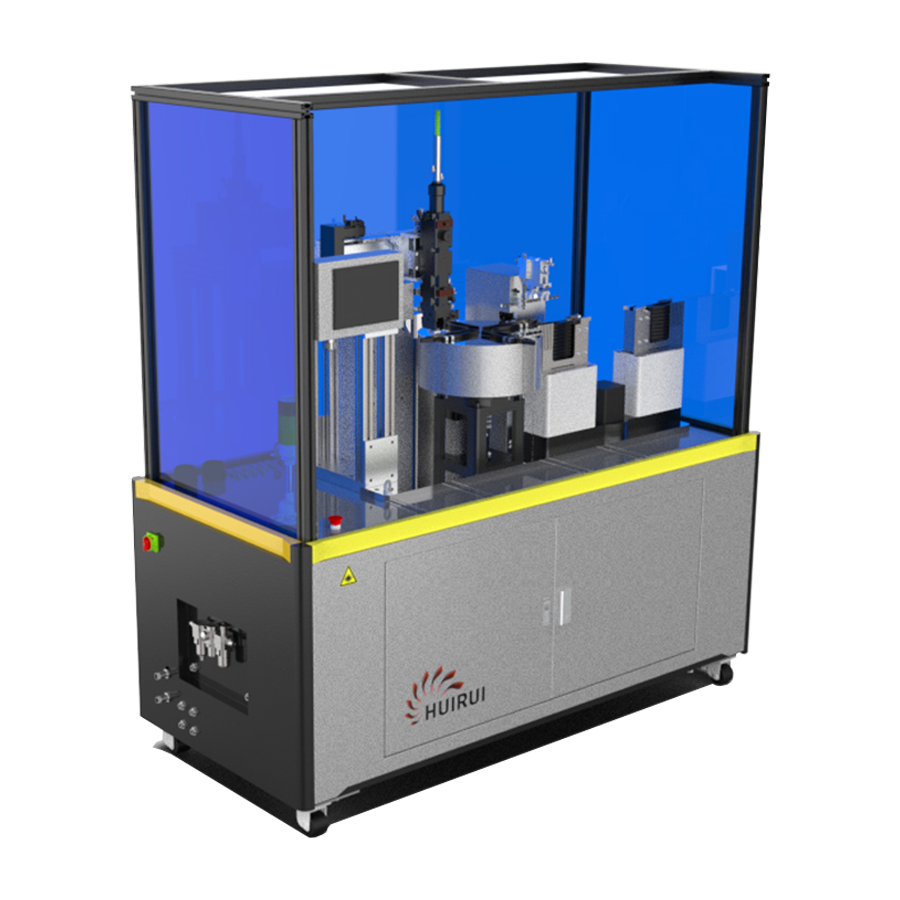

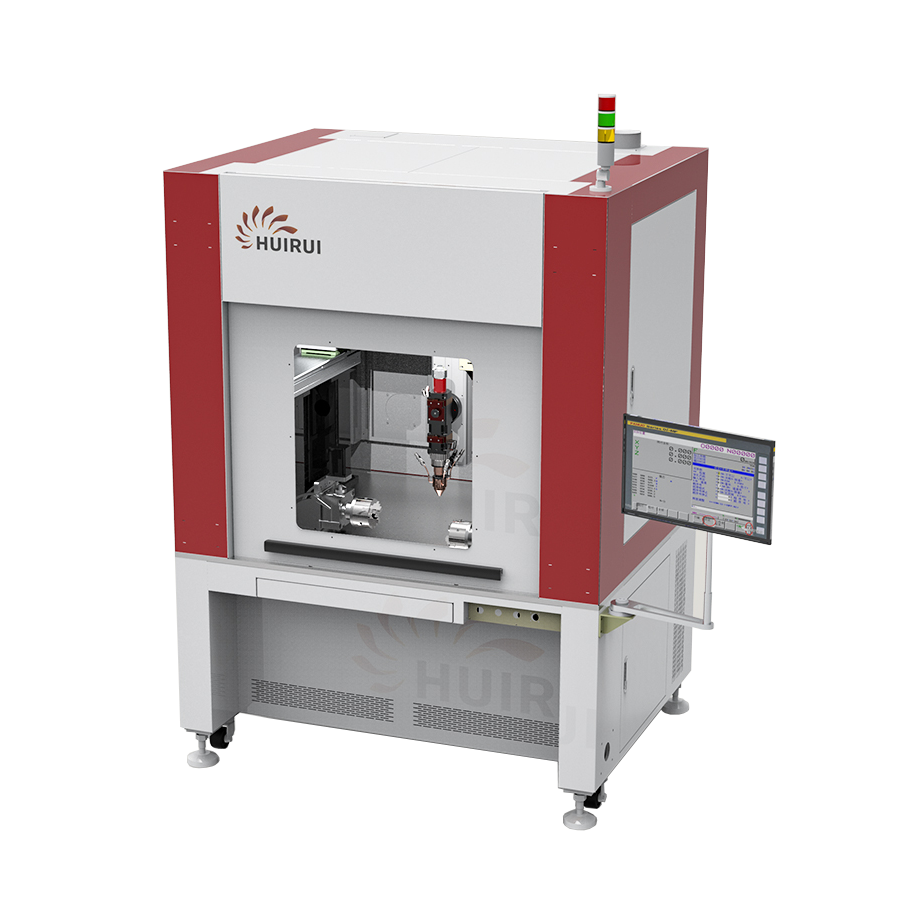

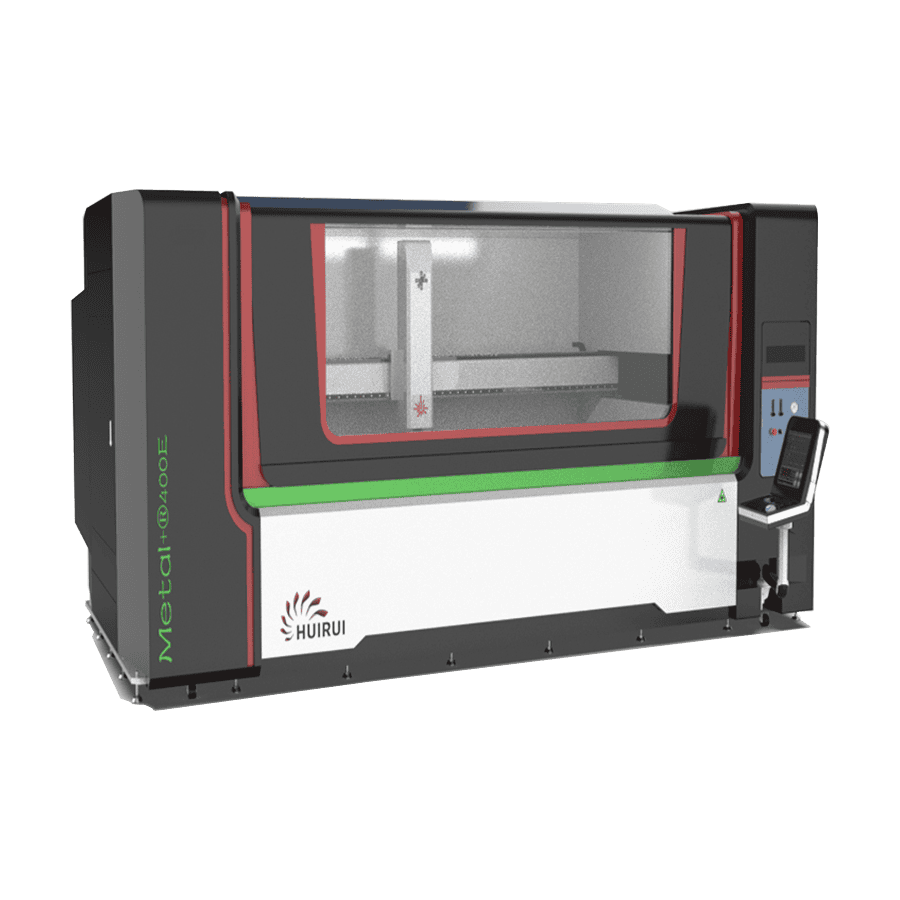

SmartVision Visual Detection Adaptive Repair System

get a free quotePresentation of the equipment's characteristics

System Introduction

SmartVision Visual Detection Adaptive Repair System

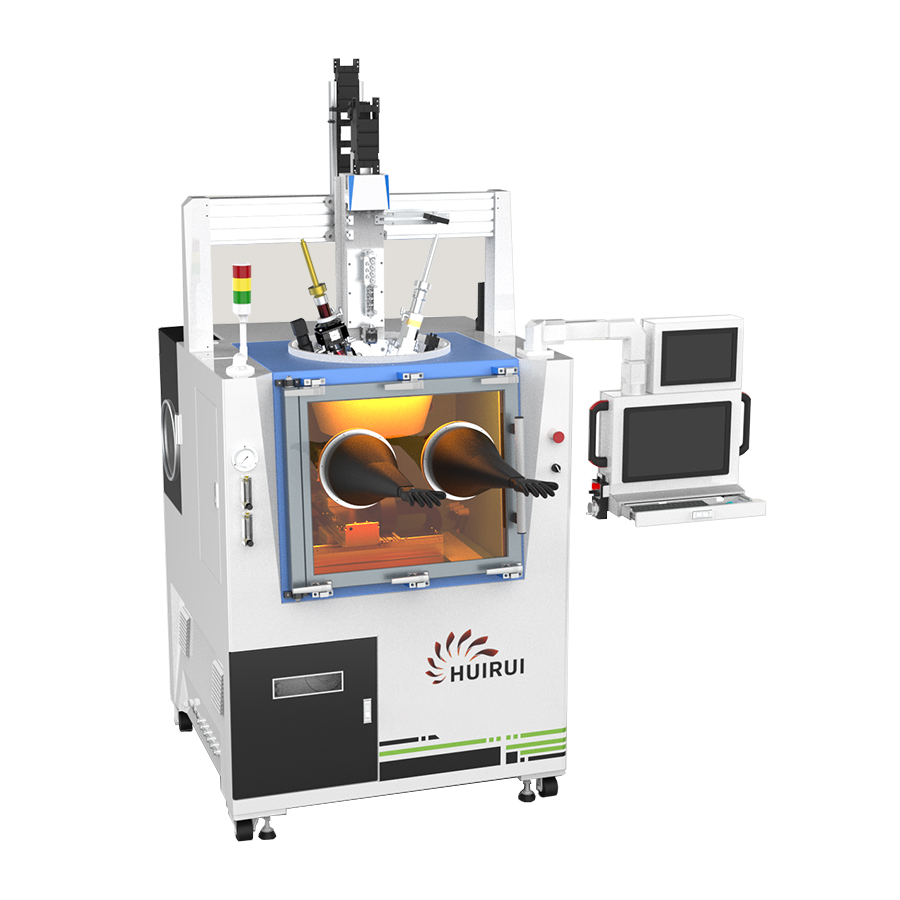

The SmartVision Visual Detection Adaptive Repair System, independently developed by Huirui Laser, is an advanced industrial solution designed to overcome process challenges in laser cladding and remanufacturing applications. These challenges often arise from irregular workpiece geometries or uneven surface profiles.

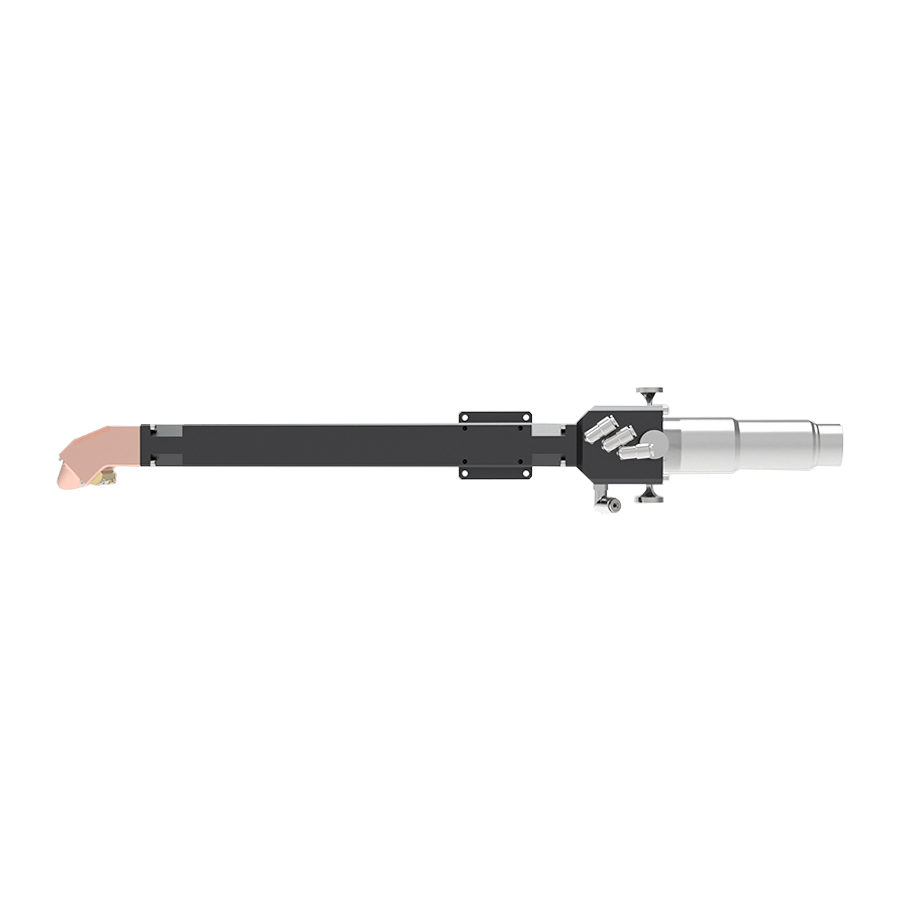

At its core, SmartVision enables “adaptive contour-following laser cladding”, allowing the laser nozzle to automatically maintain a constant distance from the workpiece surface, ensuring consistent processing quality and high operational efficiency.

Three Automated Steps for Intelligent Repair

-

Online Detection

Using contact sensors, machine vision, or laser displacement sensors, the system scans the target surface and establishes a correspondence between the sensor measurement coordinate system and the robot’s laser cladding tool coordinate system. -

Automated Data Processing

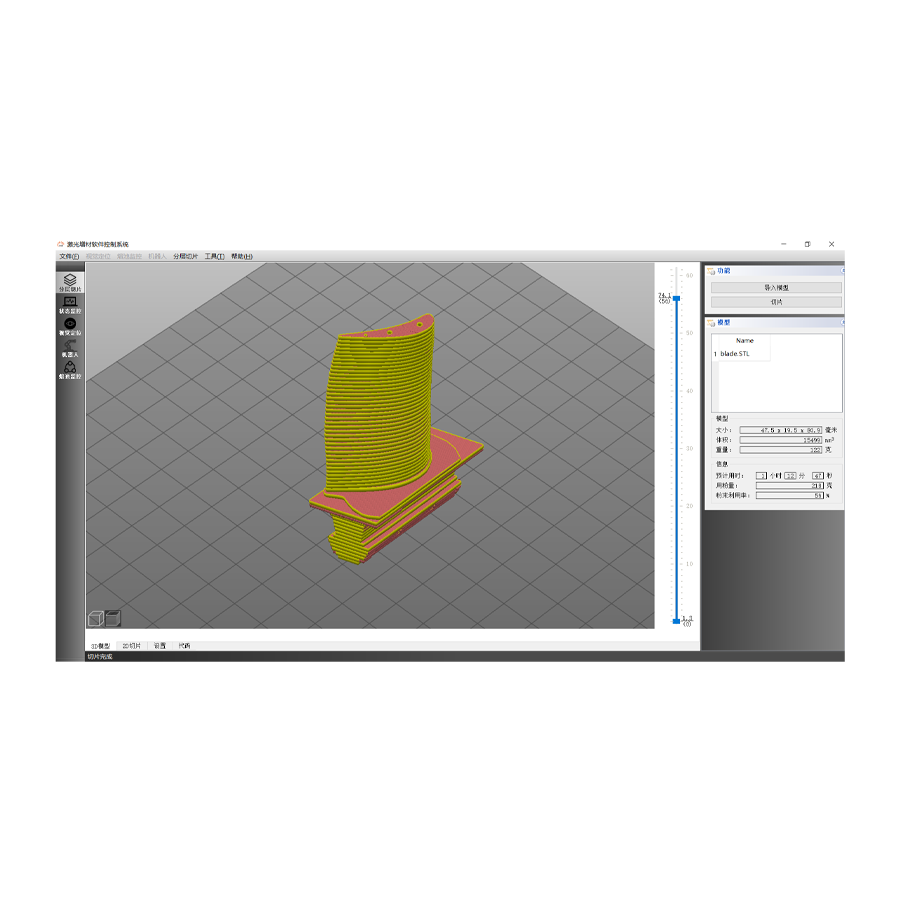

The collected data undergoes filtering, reconstruction, and 3D modeling, combined with intelligent algorithms for automatic model matching and defect recognition, ensuring precise and efficient analysis. -

Automatic Path and Parameter Generation

Based on the reconstructed 3D model, the system performs layer slicing and trajectory generation (with alternating fill angles supported). It then automatically selects and optimizes process parameters according to defect type and completes post-processing to generate executable robot programs.

System Advantages

SmartVision Visual Detection Adaptive Repair System

The advantages of the SmartVision System are best demonstrated across its three core application scenarios, showcasing its ability to enhance efficiency, accuracy, and automation in laser cladding and repair processes.

1. Enhanced Efficiency and Precision

The system significantly reduces the need for manual robot teaching and calibration, cutting down programming time while improving path planning accuracy. This breakthrough overcomes traditional limitations in high-precision laser repair, enabling faster and more consistent automated processing.

2. Intelligent Positioning and Coordinate Matching

SmartVision automatically establishes the workpiece or user coordinate system, allowing offline-programmed robotic paths to be applied quickly and accurately to real workpieces. This capability increases production speed and replaces conventional feature-point alignment methods, solving complex positioning challenges in areas that are difficult for manual detection.

3. Rapid On-Site Adaptive Repair

Equipped with an integrated 3D scanning function, SmartVision combines automatic defect recognition and path-slicing algorithms to perform fast defect localization and real-time adaptive repair. While its measurement accuracy is slightly lower than that of specialized 3D metrology systems, it fully meets laser repair requirements and offers outstanding speed, cost-efficiency, and practicality for industrial use.

Key Benefits at a Glance

-

Automates inspection, modeling, and repair for complex parts

-

Reduces programming time and human error

-

Adapts dynamically to irregular or damaged surfaces

-

Shortens maintenance cycles and lowers production costs

-

Enables reliable on-site repair with minimal downtime

Related products

HUIRUI only makes the best products in this industry