Metal+One® Compact Enclosed Metal DED 3D Printer

get a free quotePresentation of the equipment's characteristics

Product Overview

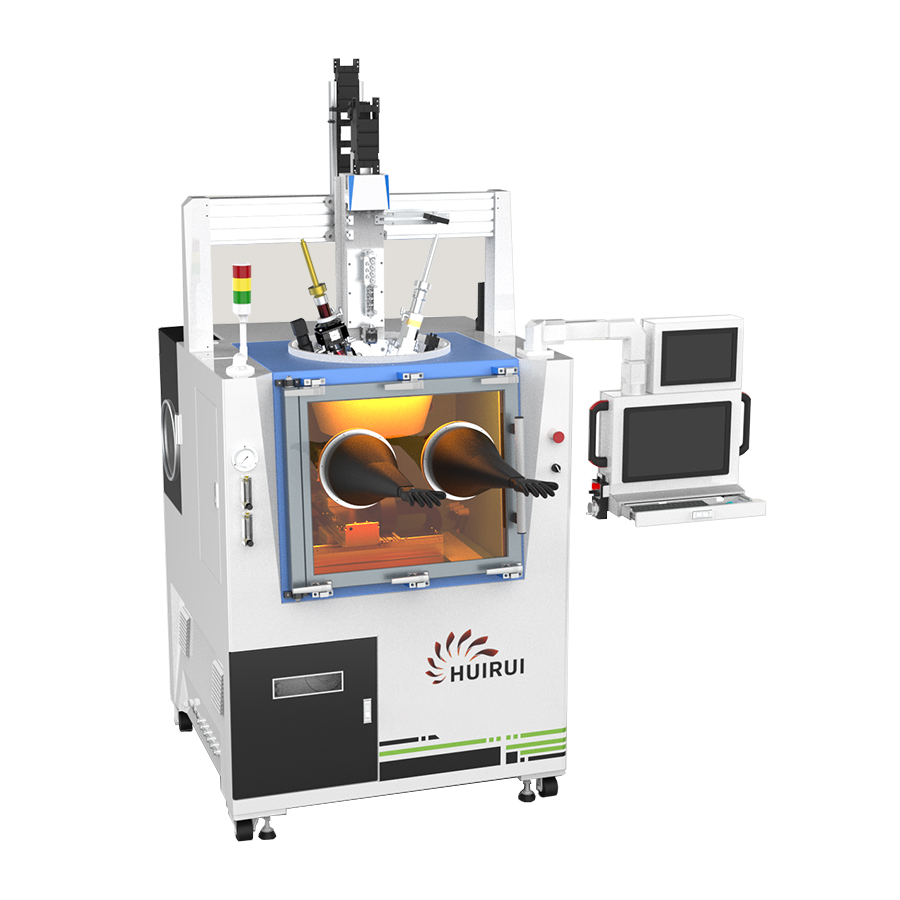

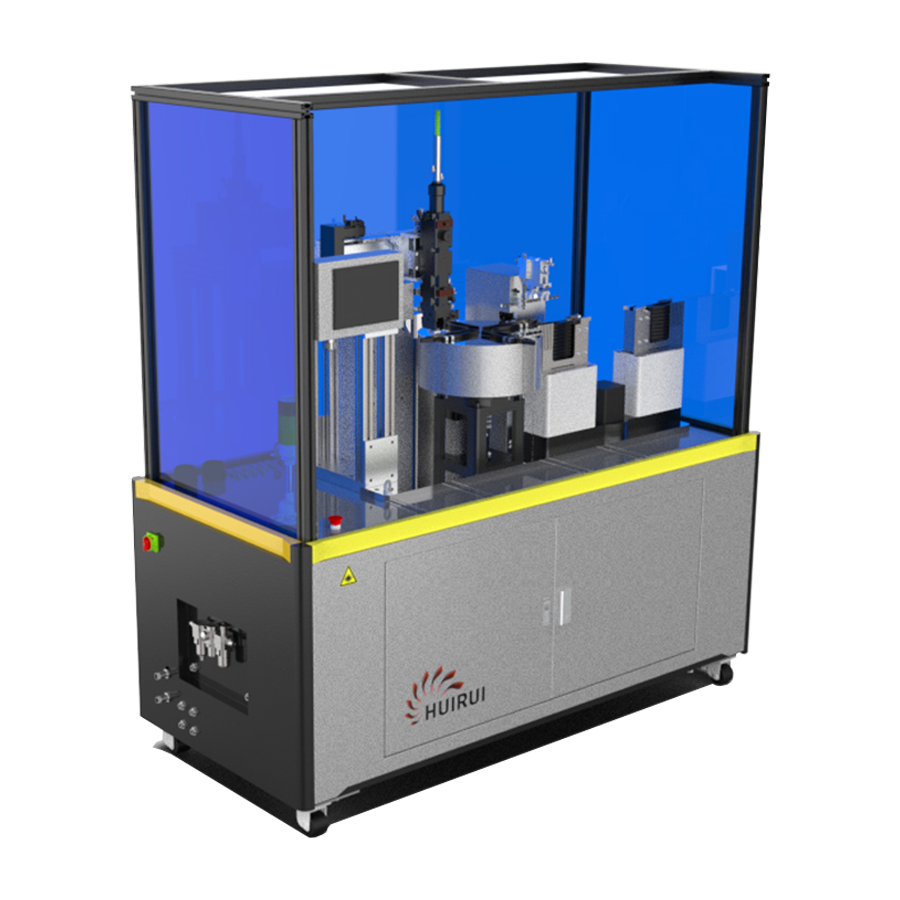

The Huirui-Laser Laser Wire Additive Manufacturing (LWAM) System is a high-precision, high-quality laser wire feeding 3D printing and welding platform, specifically engineered for advanced material processing.

Integrated within a custom-built environmental chamber, the system ensures all operations are performed under inert gas protection, preventing oxidation and contamination during the deposition process.

Equipped with a dual-laser system that supports mid-point wire feeding, the machine achieves positioning accuracy up to 0.02 mm. Its flexible sealed structure combined with CCD vision-based melt-pool monitoring enables efficient, safe, and environmentally responsible production.

Designed for industrial and research applications, it is ideal for energy and power systems, engineering machinery, mold and tooling manufacturing, and metal component repair. The system supports multi-process operations, including laser wire additive printing and laser wire welding, offering exceptional versatility for diverse production needs.

Technical Overview

Laser Wire Additive Manufacturing (LWAM) — also known as Laser Wire Deposition — is an innovative metal additive manufacturing technology that combines focused laser beams with precisely controlled metal wire feeding to achieve superior accuracy and material integrity.

Compared with traditional powder-based 3D printing, the LWAM process provides significant advantages:

-

Reduced material waste through direct wire utilization

-

Lower operational costs with minimal consumables

-

Enhanced production efficiency and higher deposition rates

-

Improved environmental and workplace safety, thanks to its closed-chamber, fume-free operation

This cutting-edge technology is widely applied across energy and power, automotive manufacturing, tooling and mold industries, and heavy equipment component repair, making it a preferred choice for high-performance metal fabrication.

Technical Features and Advantages of the Huirui-Laser LWAM System

1. High Material Utilization

The laser wire additive manufacturing (LWAM) technology precisely controls both wire feeding and laser irradiation, ensuring that only the required material is consumed during the deposition process.

This near-zero-waste approach achieves a material utilization rate close to 100%, making it far more efficient and sustainable than powder-based 3D printing methods.

2. High Production Efficiency

By optimizing the deposition path, wire feed rate, and energy control, the system delivers significantly higher productivity and shorter manufacturing cycles.

This makes it ideal for rapid prototyping, on-demand part repair, and small-batch metal production.

3. Environmental Safety and Clean Processing

Operating within a sealed inert-gas environment, the LWAM system maintains oxygen and moisture levels below 50 ppm, minimizing oxidation and contamination.

Unlike powder-based systems, it eliminates dust hazards and avoids potential environmental pollution or explosion risks, ensuring a clean, safe, and eco-friendly workspace.

4. Wide Material Compatibility

The Huirui-Laser system supports a broad range of metals and alloys, including highly reactive or flammable materials such as aluminum and magnesium alloys.

This makes it adaptable for diverse industrial sectors — from aerospace and energy to automotive and precision tooling.

Equipment Highlights and Core Advantages

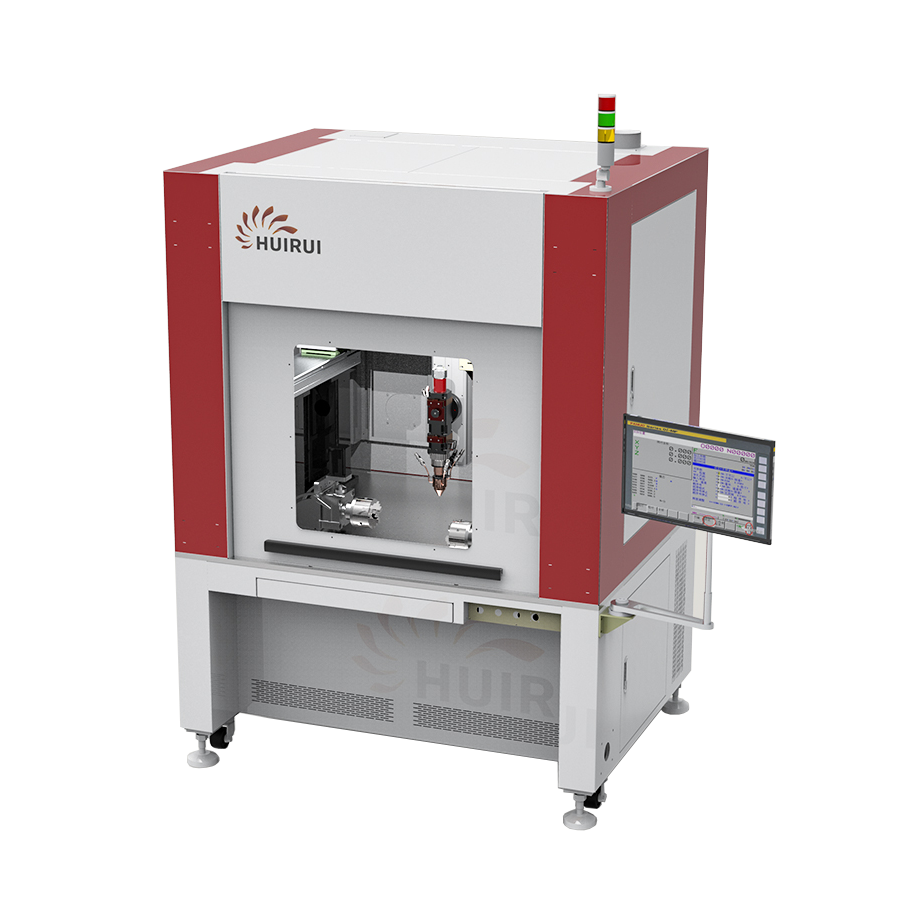

1. High-Precision Motion Control

The equipment integrates an advanced multi-axis motion control system with positioning accuracy up to 0.02 mm, guaranteeing exceptional dimensional precision and long-term process stability.

2. Flexible Sealing System

The Z-axis features a unique flexible sealing design that maintains airtight integrity while allowing smooth motion.

This reduces the overall chamber volume and improves purification efficiency, ensuring a consistent controlled environment.

3. Inert Gas Protection

Inside the chamber, inert gas shielding keeps the oxygen and moisture concentration below 50 ppm, providing a stable and oxidation-free processing atmosphere essential for high-precision laser deposition.

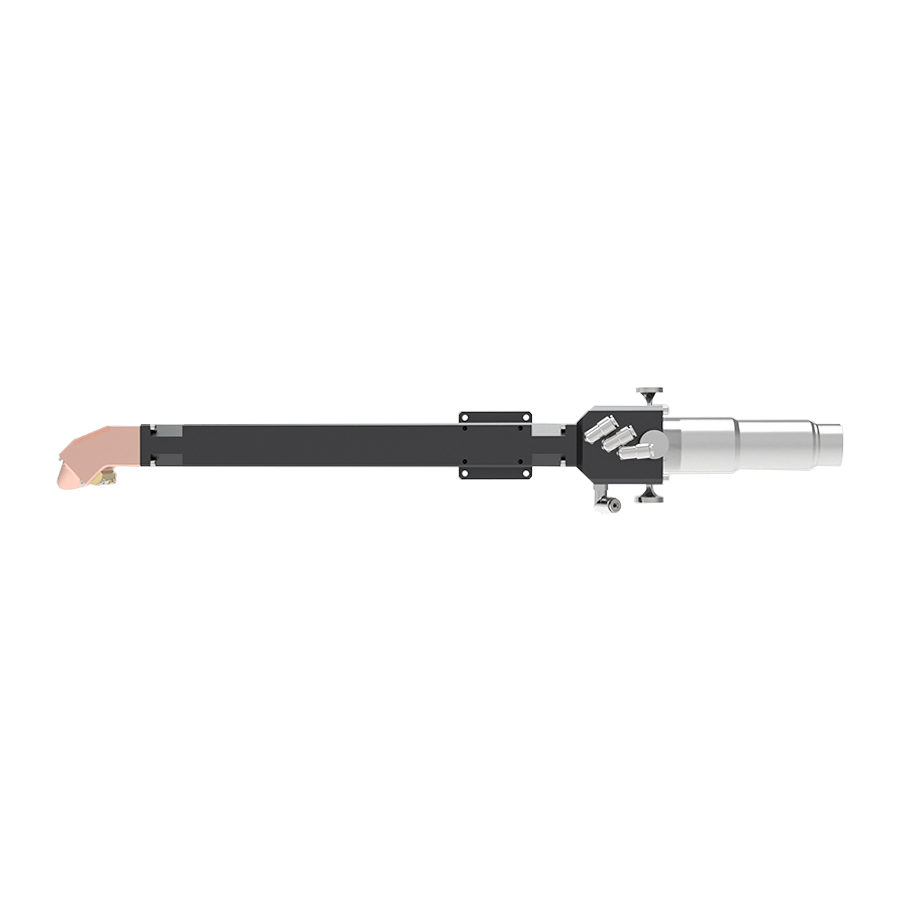

4. Dual-Laser Mid-Feed Wire System

Equipped with a dual-beam laser configuration, the system supports simultaneous or independent processing of two laser paths.

The mid-feed wire design ensures stable melting, improved deposition uniformity, and flexible adaptation to different material types or thicknesses.

5. Easy Operation and Maintenance

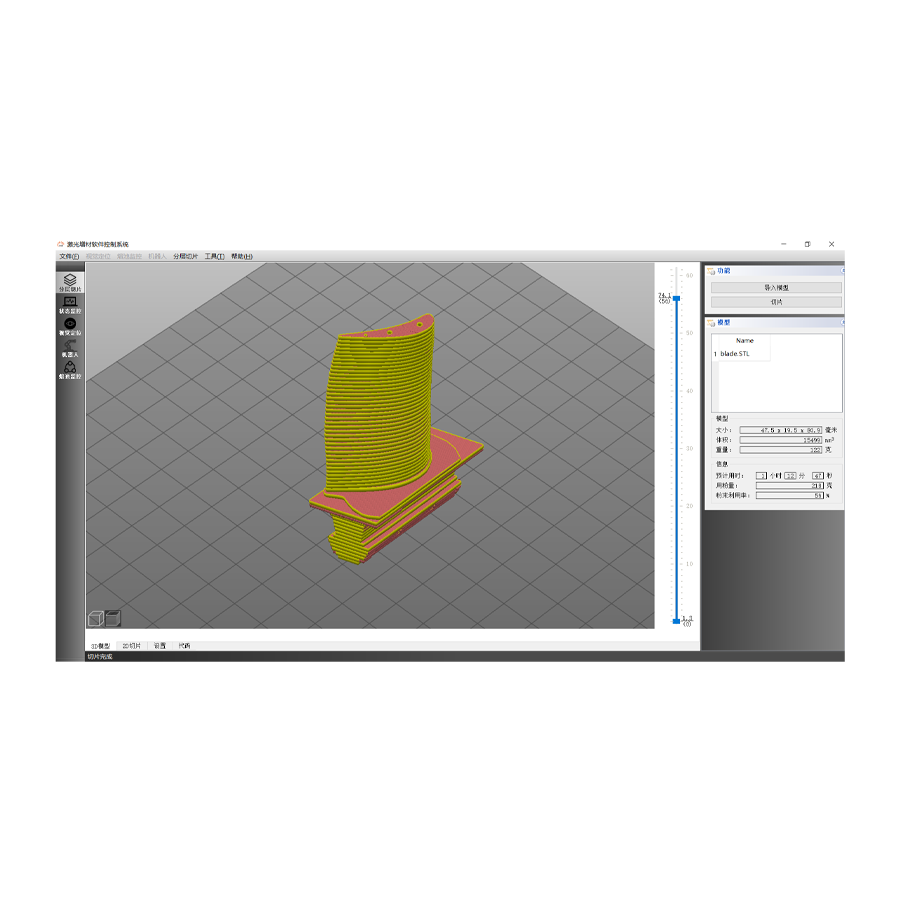

The user-friendly interface and open software architecture simplify control, parameter adjustment, and system upgrades.

Operators can quickly master the setup, calibration, and maintenance, reducing training costs and downtime.

6. Multi-Process Versatility

Beyond additive manufacturing, the system also supports laser wire welding, cladding, and hybrid additive-repair operations, making it a multi-function platform for diverse industrial applications.

7. Real-Time CCD Process Monitoring

A built-in CCD vision melt-pool monitoring system provides real-time visualization of the deposition process, wire path, and melt behavior.

This enables instant quality feedback and ensures consistent, defect-free production.

8. Ergonomic and Intelligent Design

The system’s human-centered interface offers intuitive operation and streamlined workflows.

From touchscreen controls to smart diagnostics, every feature is designed to enhance user experience and operational safety.

| Parameter | Specification |

|---|---|

| Equipment Name | Non-standard Customized Wire Feeding Printing Equipment with Environmental Chamber |

| Operation Display | Dual Screen: Operation Screen / Vision Monitoring Screen |

| Applicable Wire Diameter | 0.2-1.2 mm |

| Control System | Closed-loop Motion Control |

| Chiller | Dual Temperature Dual Control |

| Forming Size | Within 200x200x400 mm |

| Water Oxygen Content | <50 PPM |

| Laser | Fiber/Semiconductor Laser |

| Overall Size | 1.2×1.2×2.5 m |

| Wire Feeding System | Push-Pull Wire Feeding |

| Three-Axis Travel (XYZ) | 200x200x400 mm |

| Laser Power | 2 kW |

| Laser Head | Dual Straight Version |

| Positioning Accuracy | ±0.02 mm |

| Power | <5 kW |

| Spot Size | 0.2-3 mm |

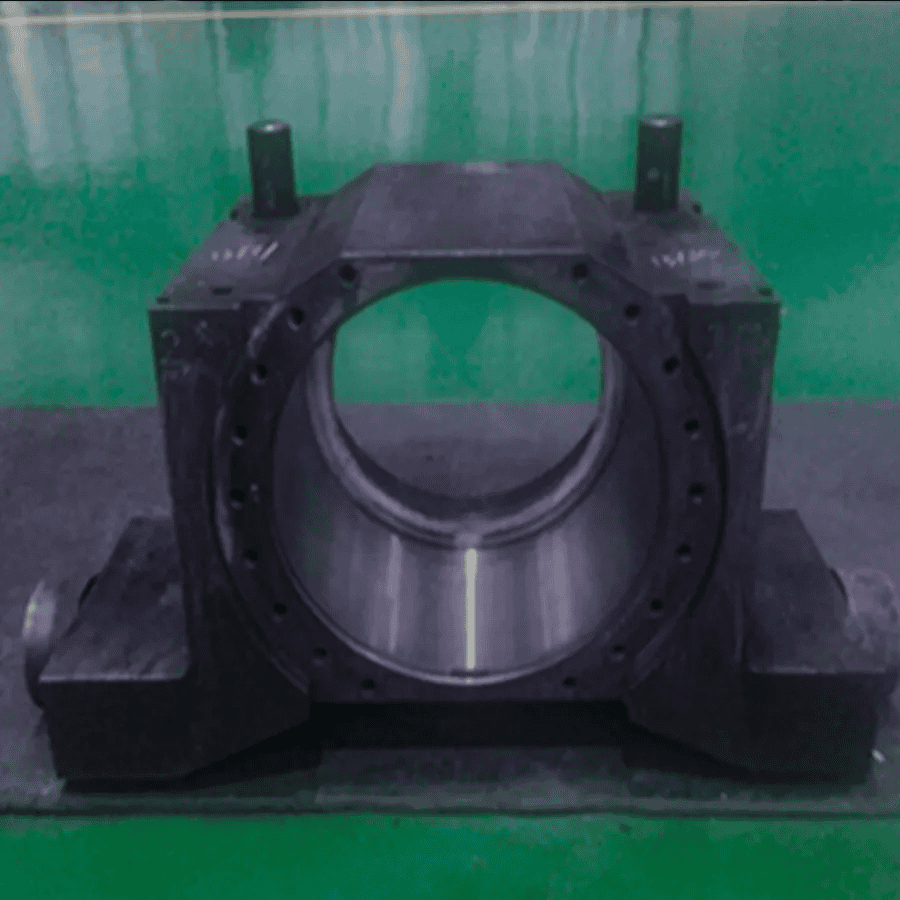

| Expandable Modules | Platform Heater, Transition Chamber, Positioner, etc. |

| Configuration Software | Path Planning Auto Software, Online Monitoring Software |

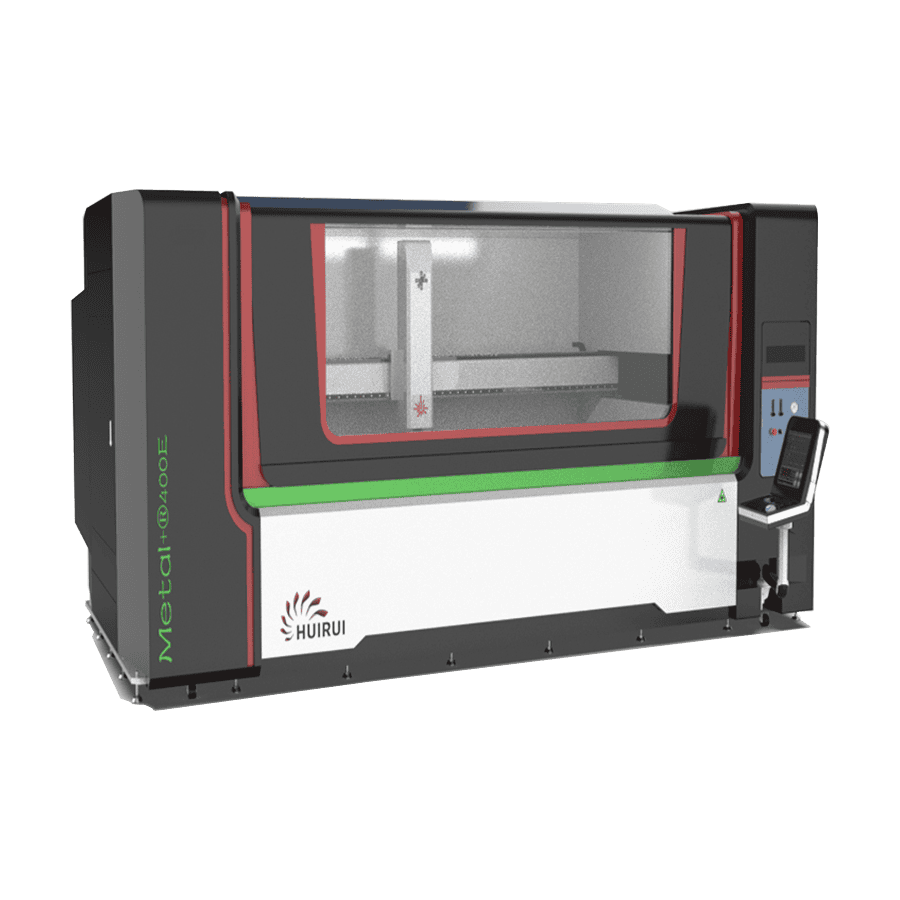

Related products

HUIRUI only makes the best products in this industry