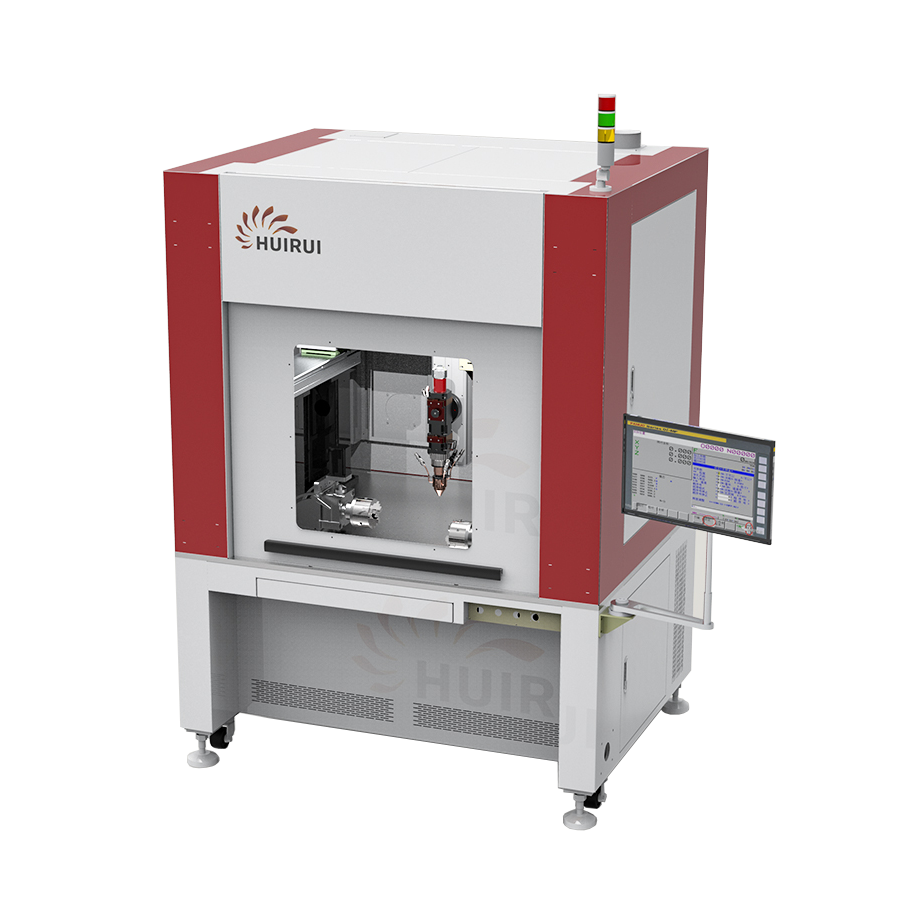

Metal+®One-40E Compact High-Throughput Metal DED 3D Printer

get a free quotePresentation of the equipment's characteristics

Product Overview

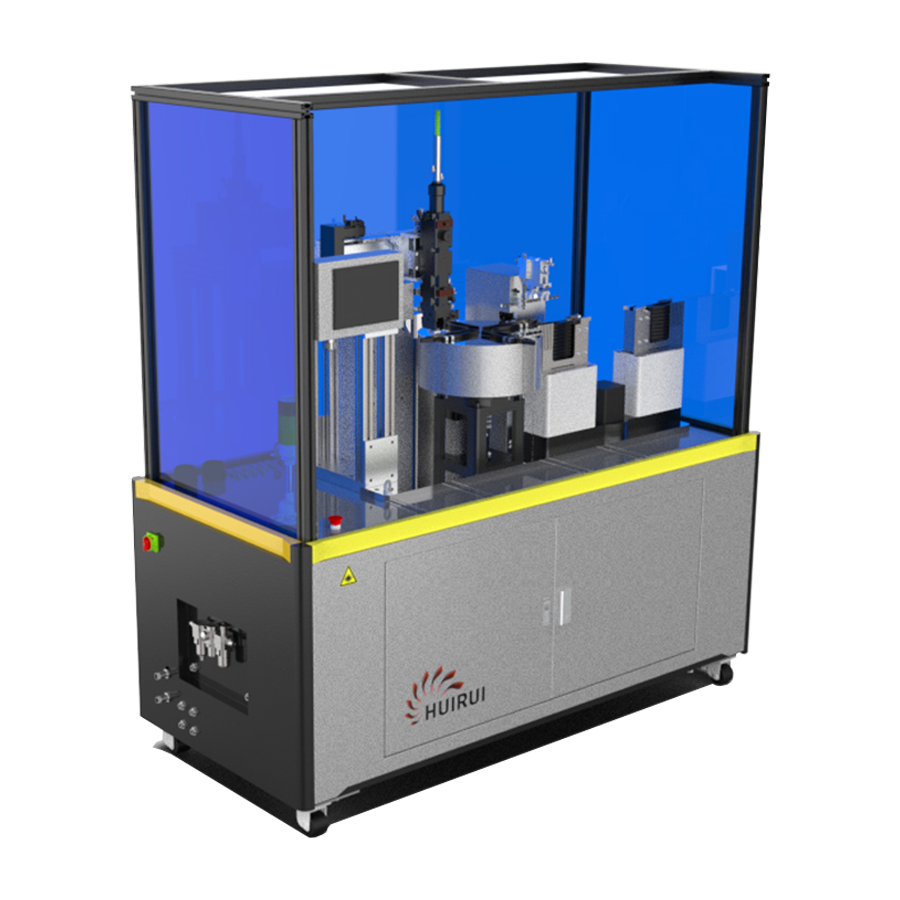

The Huirui-Laser Metal+®One Metal Direct Energy Deposition (DED) 3D Printing System is a compact, high-precision additive manufacturing platform specially developed by the Huirui-Laser technical team to address the limitations of traditional industrial laser cladding equipment.

Designed for universities, research institutes, and metal powder manufacturers, this small yet powerful system delivers high-performance metal printing with minimal powder consumption and exceptional flexibility for material research.

Key Features

-

Compact and Efficient Design: Small footprint, low powder usage, and optimized chamber design make it ideal for laboratory environments and R&D applications.

-

Multi-Powder Feeding System: Equipped with multiple precision powder feeders, allowing real-time multi-material mixing with accurate and controllable ratios.

-

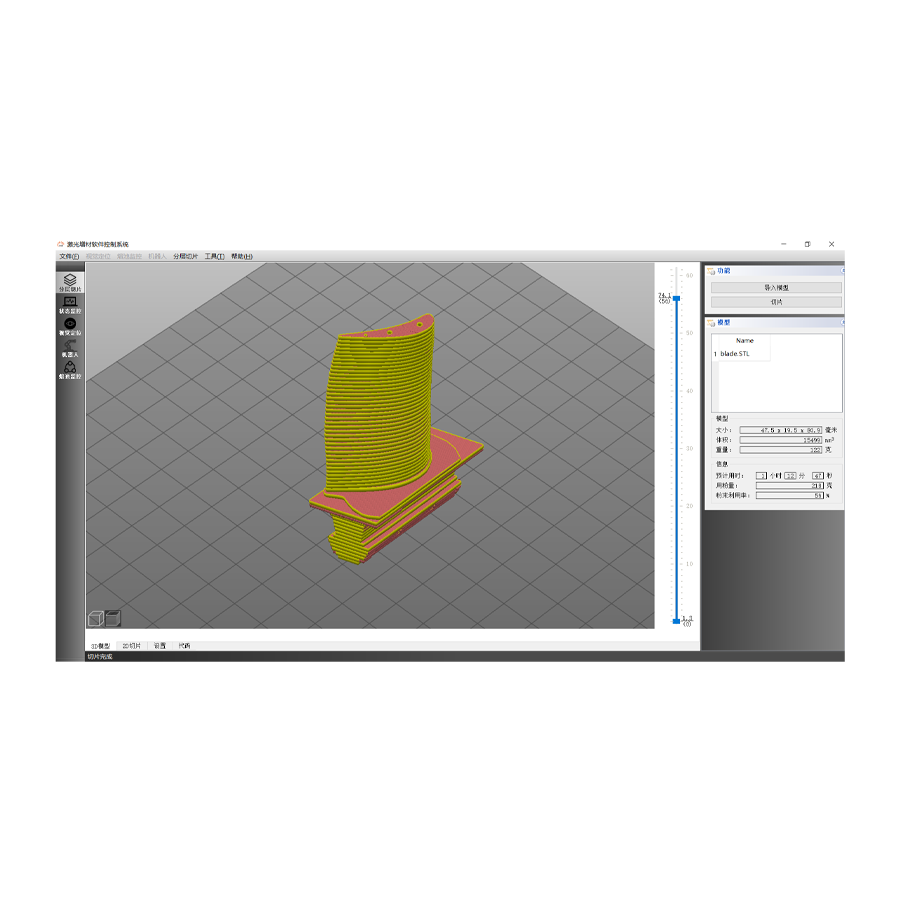

High-Throughput Experiment Software: Integrated dedicated experimental software supports batch printing of multiple samples with varying compositions in one run, significantly boosting research productivity.

-

Exceptional Powder Utilization: The system achieves high material efficiency, reducing waste and lowering operating costs.

-

Flexible Composition Control: Enables quick adjustment of alloy proportions and gradient transitions for advanced material development.

-

Broad Material Compatibility: Suitable for steel, aluminum alloys, titanium alloys, nickel-based superalloys, high-entropy alloys, and ceramic powders, making it perfect for composition screening, performance testing, and gradient material studies.

Ideal for

-

Material science laboratories

-

University and institutional research

-

Powder metallurgy and additive manufacturing R&D

-

New alloy development and gradient material studies

Key Features of the Huirui-Laser Metal+®One Metal DED 3D Printer

-

Ultra-High Motion Precision

With positioning accuracy up to 0.02 mm, the system ensures every print is executed with exceptional precision and repeatability—ideal for fine-detail additive manufacturing and research applications. -

Rapid Forming Cycle

Equipped with intelligent path-planning software, the system allows mold-free, direct printing of complex geometries, dramatically shortening R&D and prototyping cycles. -

Advanced Atmosphere Protection Technology

The fully enclosed inert-gas chamber maintains oxygen and moisture levels below 1 ppm, effectively preventing oxidation and ensuring material purity throughout the printing process. -

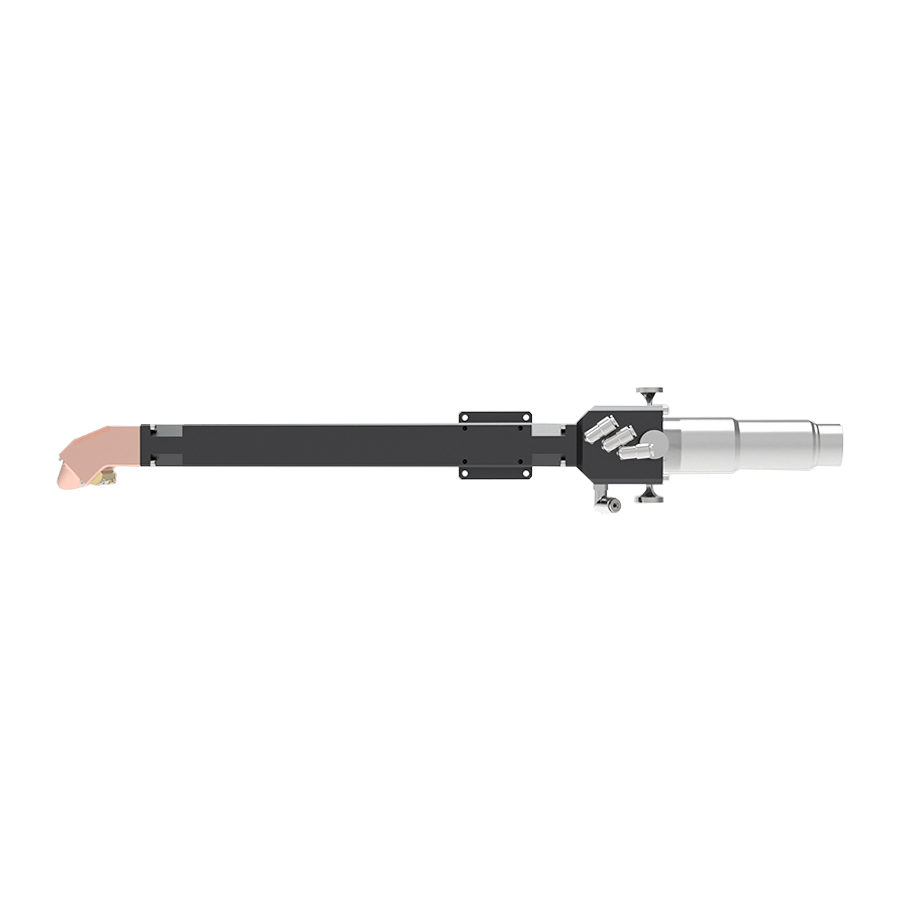

Real-Time Process Visualization

Integrated coaxial visual positioning and monitoring system enables live observation of the melt pool and deposition process, ensuring consistent and controllable print quality. -

Intuitive Operating System

The open and user-friendly software interface simplifies setup, parameter tuning, and system maintenance, minimizing the learning curve for operators and researchers. -

Versatile Multi-Process Capability

Supports laser cladding, surface repair, and direct metal 3D printing, offering a multi-functional solution that maximizes equipment utilization across diverse applications. -

Ergonomic & User-Centered Design

The system’s human-oriented layout and control interface are designed for convenience, safety, and improved user experience, ensuring smooth day-to-day operation.

| Parameter | Specification |

|---|---|

| Equipment Name | Compact High-Throughput Metal Material 3D Printing Equipment |

| Equipment Model | Metal+®one-40E |

| Operation Display | 23.8 inch/Touch Screen |

| Control System | Closed-loop Motion Control |

| Laser | Fiber/Semiconductor Laser |

| Laser Power | 2-10 kW |

| Chiller | Dual Temperature Dual Control |

| Overall Size | 1.6×1.5×2 m |

| Forming Size | Within 300x400x250 mm |

| Positioning Accuracy | ±0.02 mm |

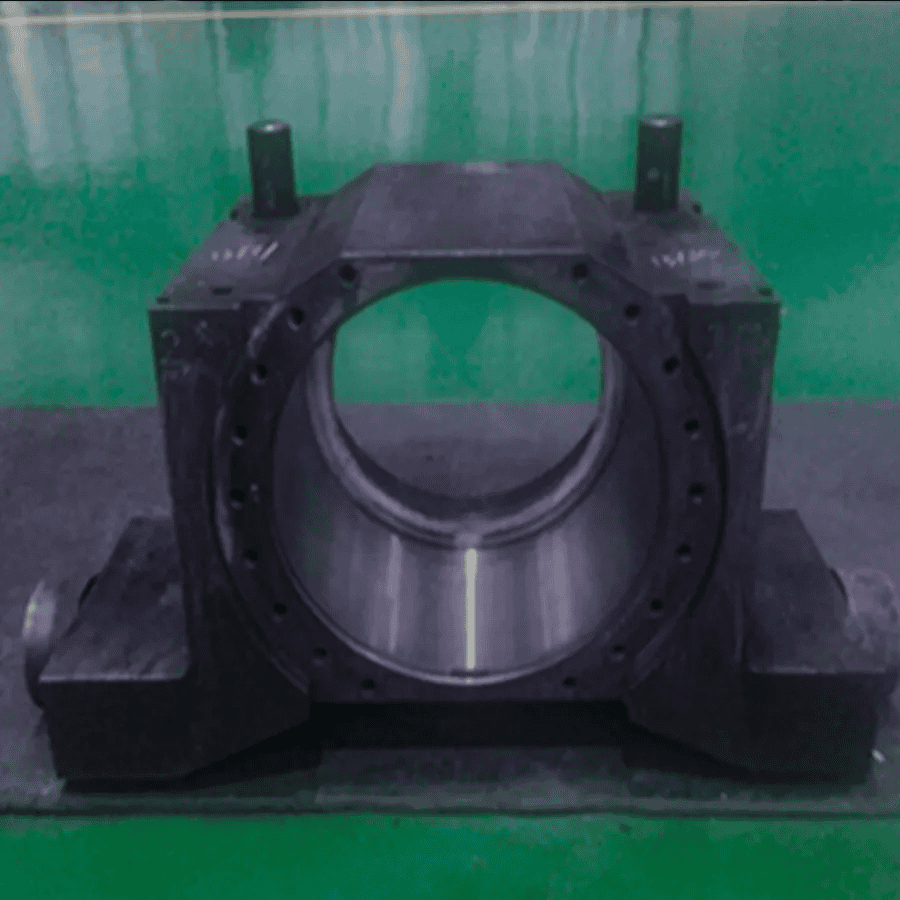

| Laser Head | Straight/Curved Version Laser Head |

| Power | <5 kW |

| Powder Feeder | Optional 4~6 Canisters |

| Cladding Nozzle | Four-Point/Annular Nozzle |

| Water Oxygen Content | <1 ppm |

| Three-Axis Travel (XYZ) | 300x400x250 mm |

| Spot Size | 0.4~6 mm |

| Expandable Modules | Platform Heater, Transition Chamber, Glove Box, Positioner, etc. |

| Configuration Software | Path Planning Auto Software, Online Monitoring Software, Visual Positioning |

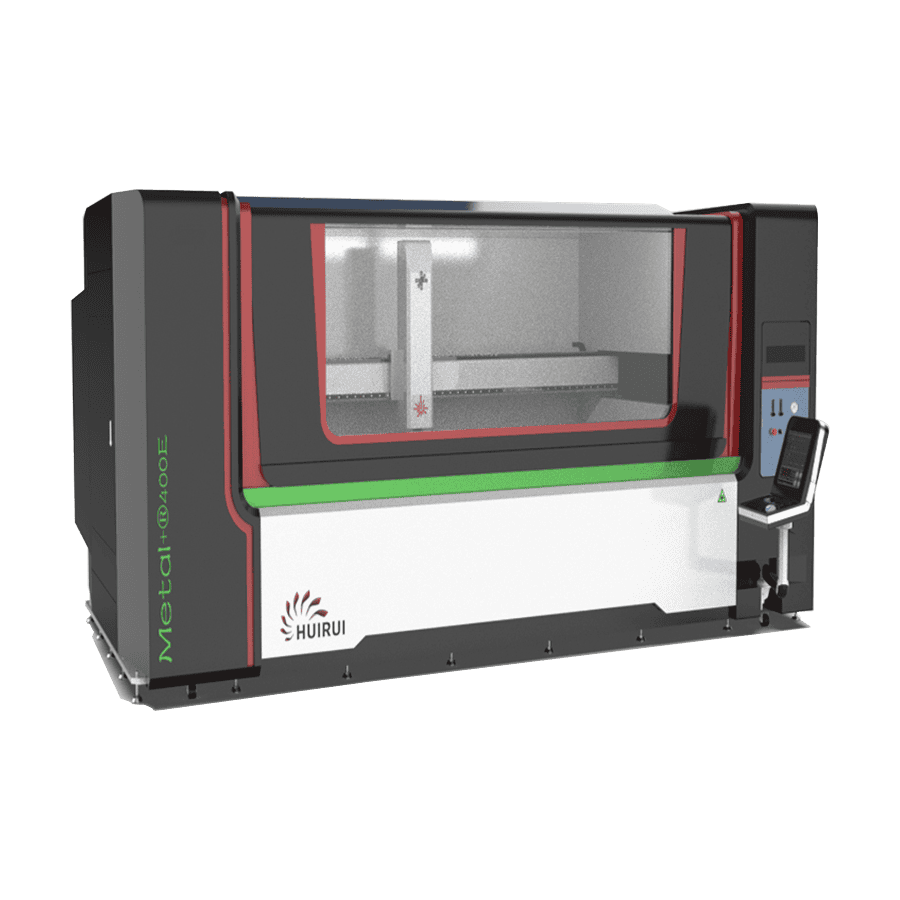

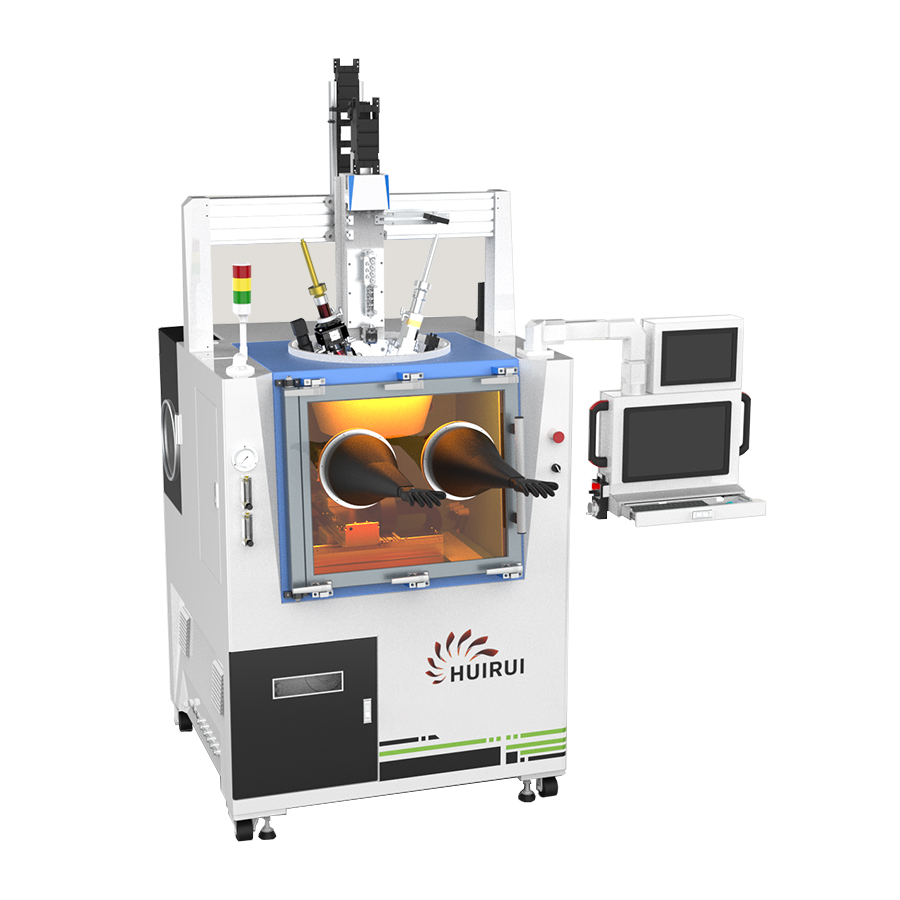

Related products

HUIRUI only makes the best products in this industry