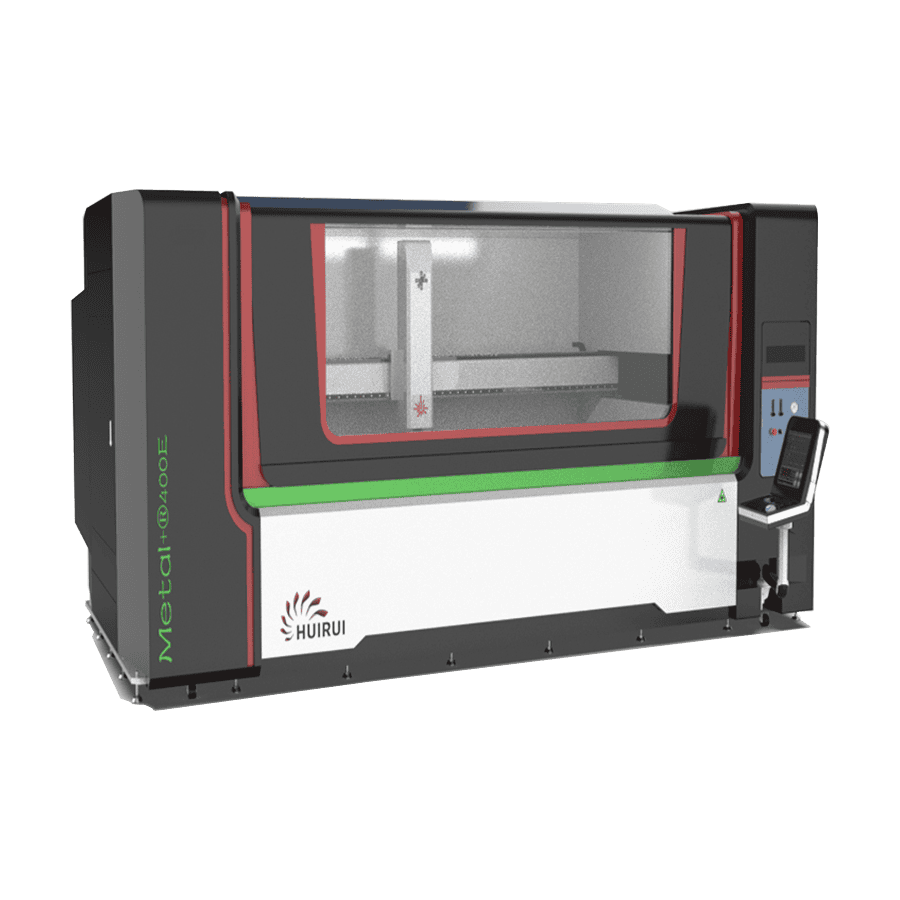

Metal+®400E Ultra-Large High-Throughput Metal DED 3D Printer

get a free quotePresentation of the equipment's characteristics

Product Overview

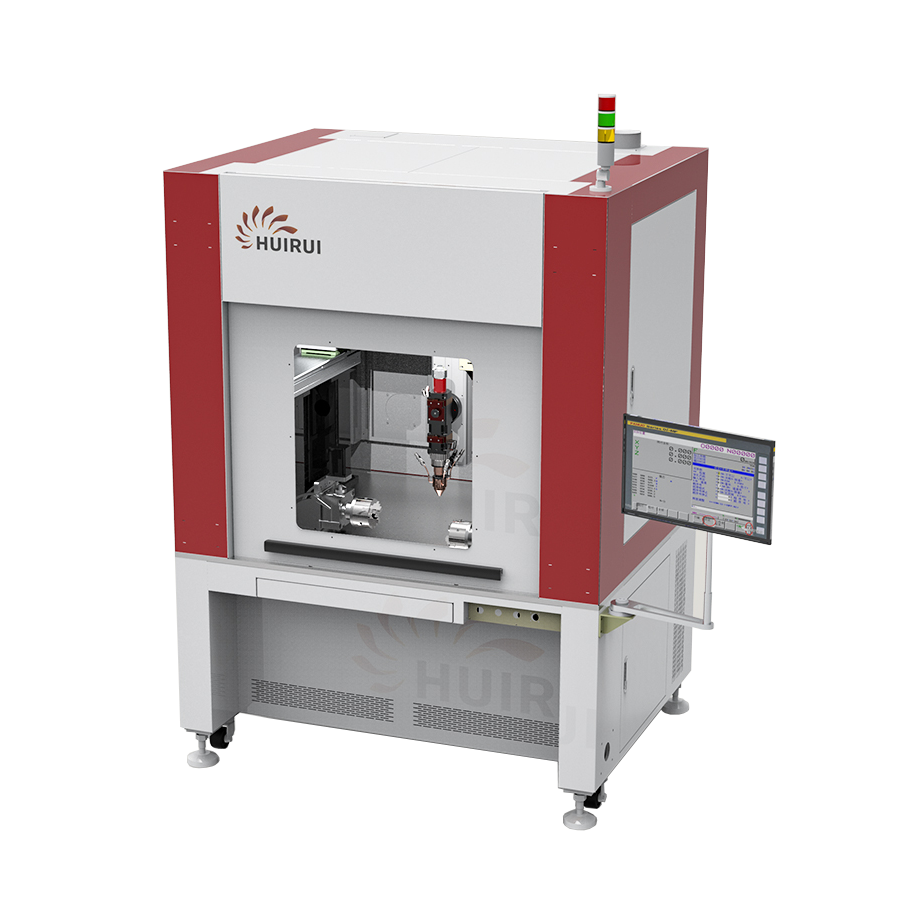

The Huirui-Laser Large-Scale Metal Direct Energy Deposition (DED) 3D Printing System is an advanced laser additive manufacturing solution independently developed by Huirui-Laser.

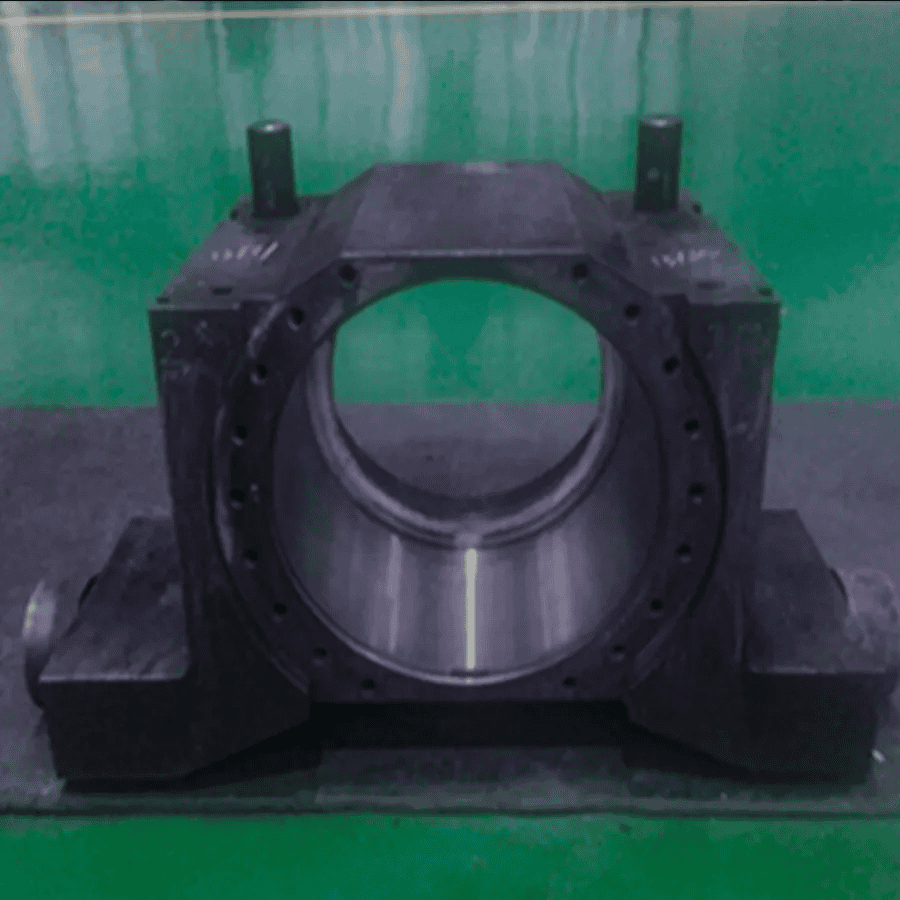

Built around laser fusion and coaxial powder feeding technology, the system deposits metal powder layer by layer along a pre-programmed tool path to achieve rapid, mold-free fabrication of complex metal components.

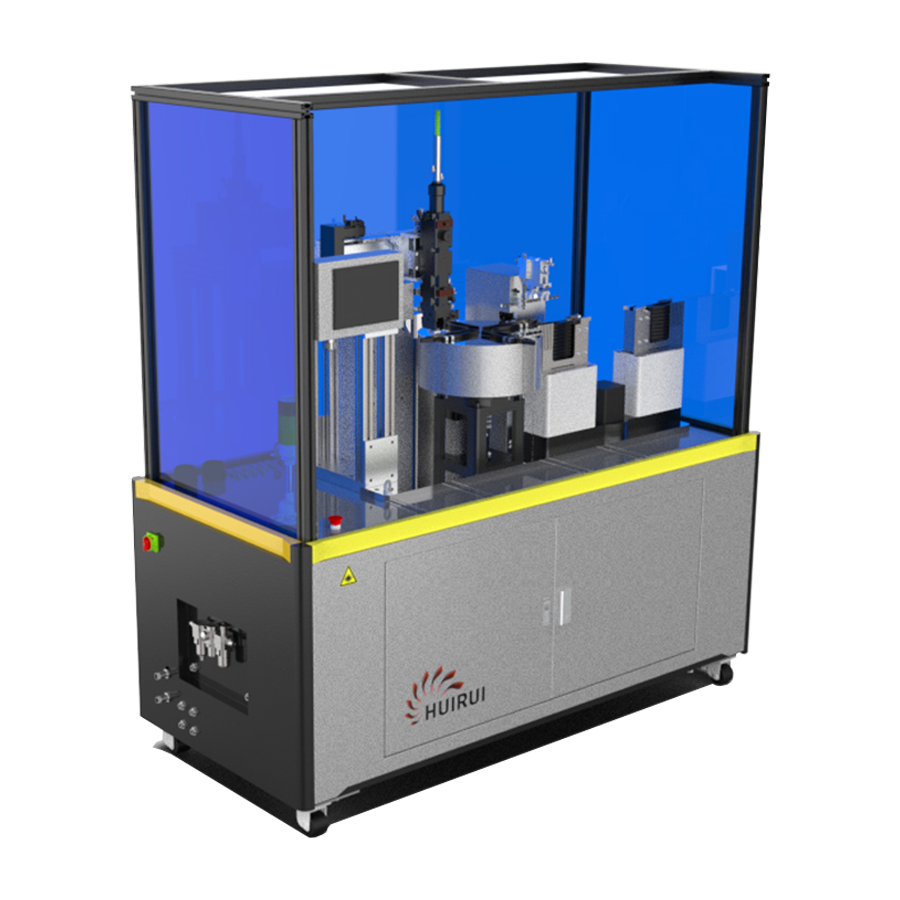

The equipment integrates a fully sealed inert-gas chamber, dust extraction unit, high-power laser source, precision laser head, mechanical motion system, multi-channel powder feeder, and industrial-grade water-cooling system.

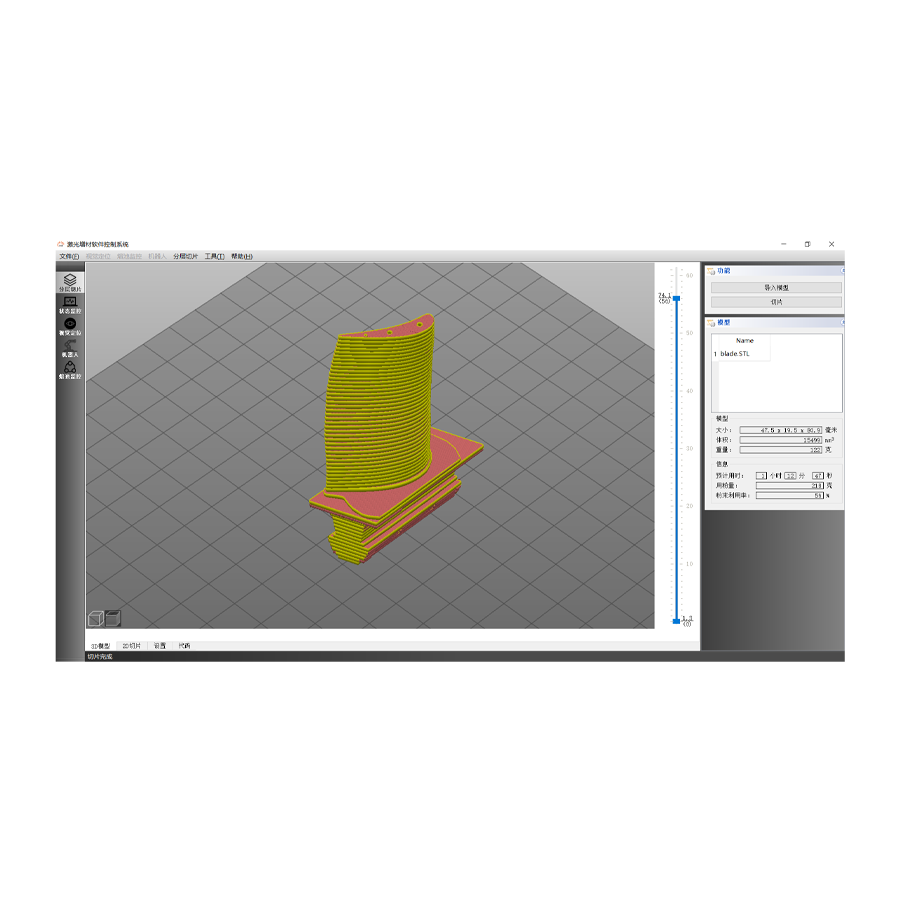

It is complemented by intelligent software modules for path planning, fault diagnostics, integrated control, process database management, and simulation analysis, creating a comprehensive and automated additive manufacturing platform.

Engineered for large and complex metal structures, this system supports agile manufacturing and high-precision repair of metal parts, significantly improving production efficiency, flexibility, and process reliability.

The Metal+ series represents a major step forward in the intelligent, high-efficiency evolution of the metal processing industry.

Key Features of the Huirui-Laser Large Metal DED 3D Printing System

-

High-Precision Positioning

The system delivers positioning accuracy up to 0.02 mm, ensuring exceptional dimensional precision and stability throughout the metal additive manufacturing process. -

Rapid Forming Capability

Powered by dedicated path-planning software, the printer enables mold-free fabrication of complex geometries, greatly reducing production and development cycles. -

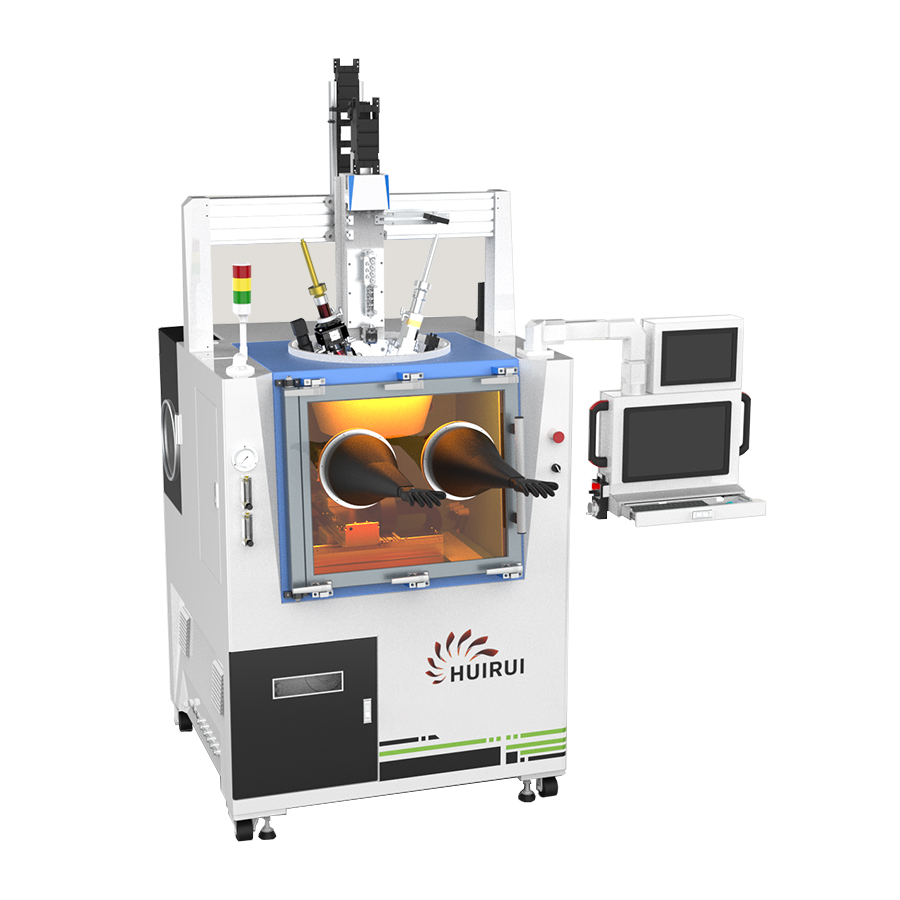

Inert Gas Protection System

Operates within a sealed inert-gas chamber, maintaining oxygen and moisture levels below 50 ppm to prevent oxidation and ensure superior surface quality of printed parts. -

Real-Time Visualization

Features coaxial vision positioning and monitoring, allowing operators to observe the melt pool and deposition process in real time, improving process transparency and quality control. -

Intuitive and User-Friendly Operation

Designed with an open and easy-to-use software and hardware system, enabling straightforward operation, simplified maintenance, and reduced operator training time. -

Multi-Process Functionality

Supports laser cladding, surface restoration, and direct metal 3D printing, offering versatile process integration within a single platform to maximize equipment utilization. -

Ergonomic Interface Design

The human-centered control interface ensures efficient, comfortable operation, providing an enhanced user experience for industrial and research environments. -

Modular Customization Options

The system supports modular expansion, including automatic transition chambers, automated loading/unloading, and mobile platforms, allowing flexible configuration for specific manufacturing requirements.

| Parameter | Specification |

|---|---|

| Equipment Name | Ultra-Large High-Throughput Metal Material 3D Printing Equipment |

| Equipment Model | Metal+®400E |

| Control System | Closed-loop Motion Control |

| Overall Size | 4.1×3.3×2.6 m |

| Laser | Fiber/Semiconductor Laser |

| Laser Power | 2-10 kW |

| Chiller | Dual Temperature Dual Control |

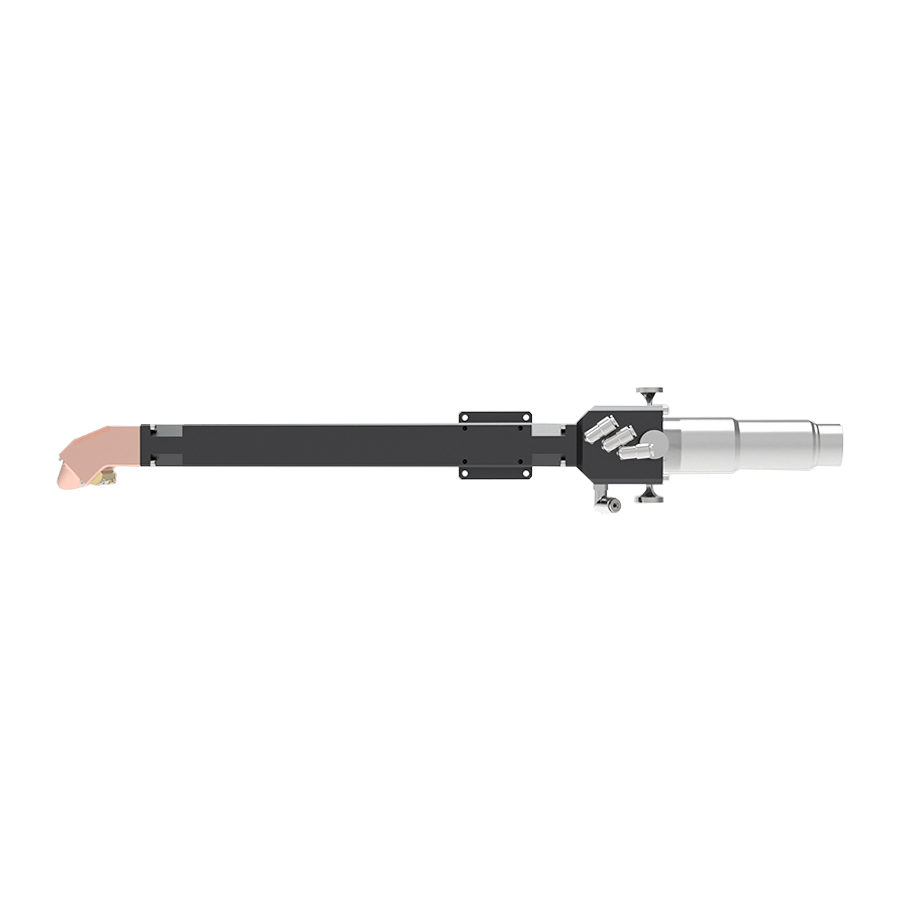

| Laser Head | Straight/Curved Version Laser Head |

| Power | <10 kW |

| Forming Size | Within 2x2x1 m |

| Powder Feeder | Optional 2~6 Canisters |

| Cladding Nozzle | Three-Point/Annular Nozzle |

| Water Oxygen Content | <50 ppm |

| Three-Axis Travel (XYZ) | 2x2x1 m |

| Positioning Accuracy | ±0.02 mm |

| Spot Size | 0.4~6 mm |

| Expandable Modules | Platform Heater, Transition Chamber, Glove Box, Positioner, etc. |

| Configuration Software | Path Planning Auto Software, Online Monitoring Software |

Related products

HUIRUI only makes the best products in this industry