Fine powder feeder

get a free quotePresentation of the equipment's characteristics

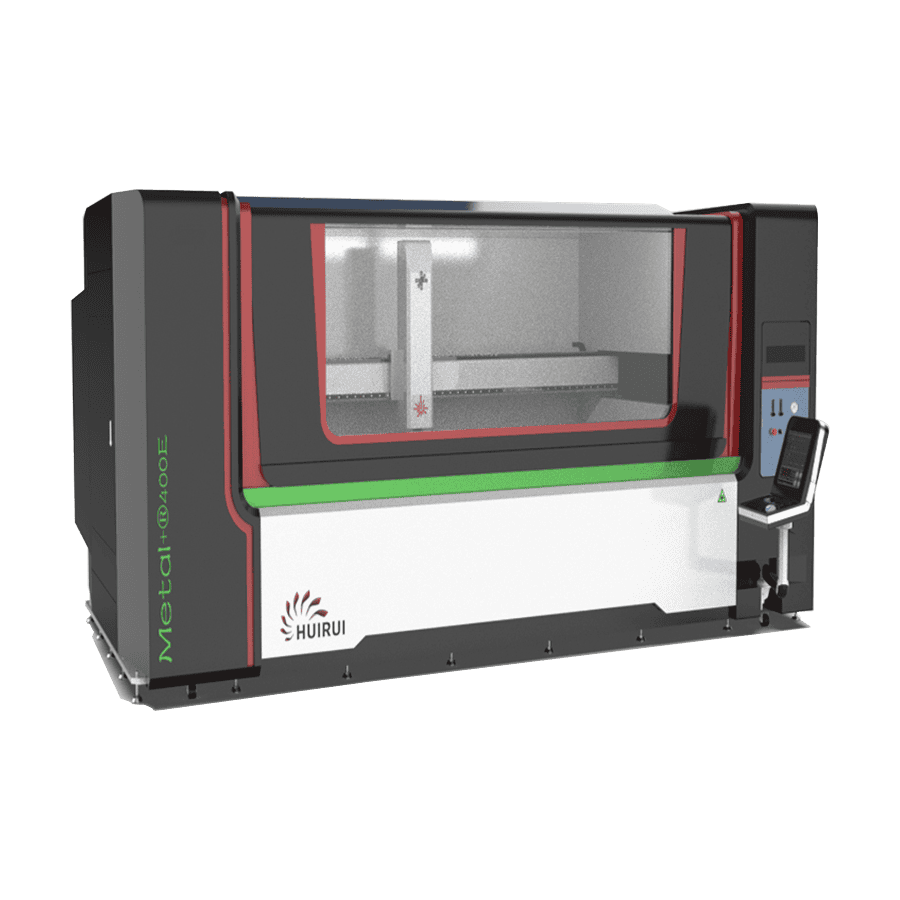

Equipment Introduction

Fine Powder Feeding Dispenser

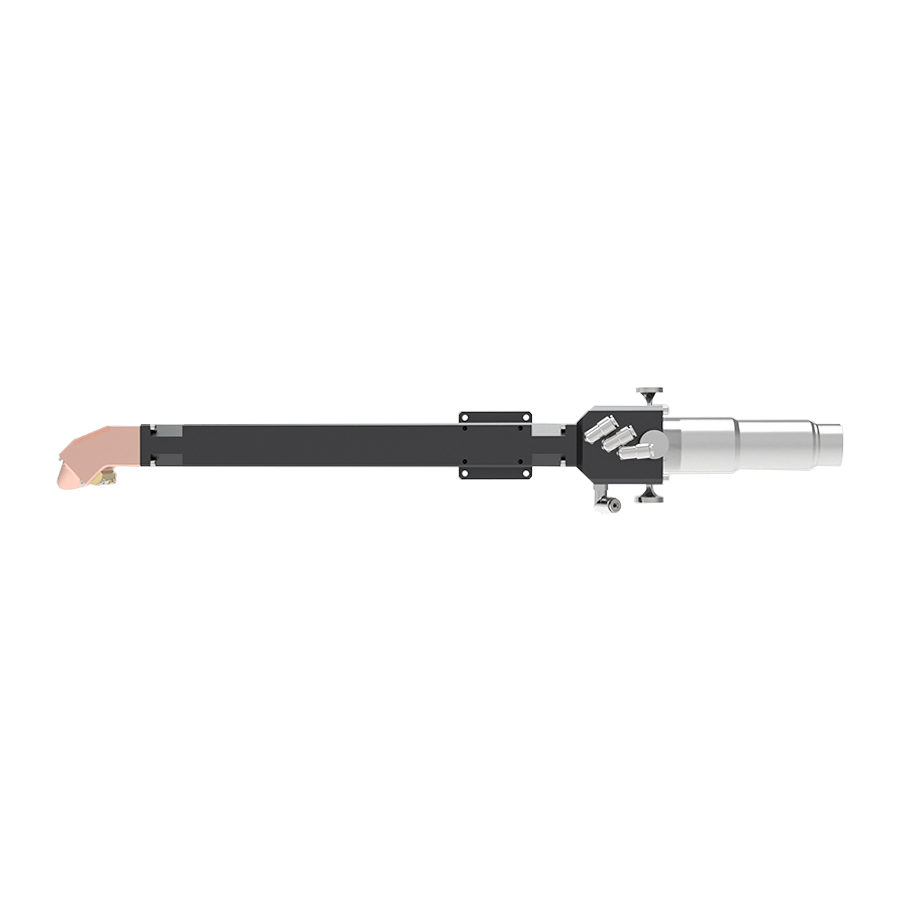

The Fine Powder Feeding Dispenser uses linear electromagnetic vibration technology as its core mechanism. Based on the principle of electromagnetic attraction and vibration, the system delivers powder from a large-capacity 22L sealed hopper into a vibrating trough. Under the vibration effect, the powder is pushed steadily to the outlet and then conveyed through pressurized airflow into the pipeline for continuous, long-distance powder transport.

Its sealed chamber design prevents powder loss during delivery, while the multi-layer feeding structure ensures stable, non-fluctuating output. Equipped with various outlet specifications, the system allows precise control of powder flow rate to meet different application needs. The large powder hopper supports long-term, uninterrupted operation, making it ideal for both large-area spraying and high-volume production.

Designed for fine, non-metallic, synthetic, and crystalline powders, this dispenser provides exceptional stability and precision, guaranteeing reliable material delivery even in demanding industrial environments.

Key Features and Advantages

-

Electromagnetic Vibration Feeding: Ensures smooth, continuous, and accurate powder delivery.

-

Sealed Transmission System: Prevents contamination and powder loss during long-distance conveying.

-

Stable Output: Layered feeding structure maintains consistent flow without fluctuation.

-

Large-Capacity Hopper (22L): Supports extended, continuous operations with minimal refilling.

-

Adjustable Output Ports: Enables precise powder flow control for different production requirements.

-

High Efficiency: Suitable for large-scale coating, additive manufacturing, and industrial processing tasks.

Equipment Advantages

-

Wide Applicability

Specifically designed for fine, non-metallic, synthetic, and crystalline powders, as well as high-volume powder feeding tasks. It can handle powders that conventional feeders struggle to process, making it suitable for a variety of complex industrial conditions. -

High-Efficiency and Stable Feeding

Utilizes linear electromagnetic vibration technology combined with a sealed chamber structure to ensure long-distance, stable powder transport. The multi-layer feeding design further enhances the uniformity and reliability of powder flow. -

Large Capacity for Continuous Operation

Equipped with a 22L large-capacity hopper, a single fill supports long-term, continuous, and large-area operations. The system maintains consistent discharge even at high or low powder levels, ensuring reliable feeding throughout production. -

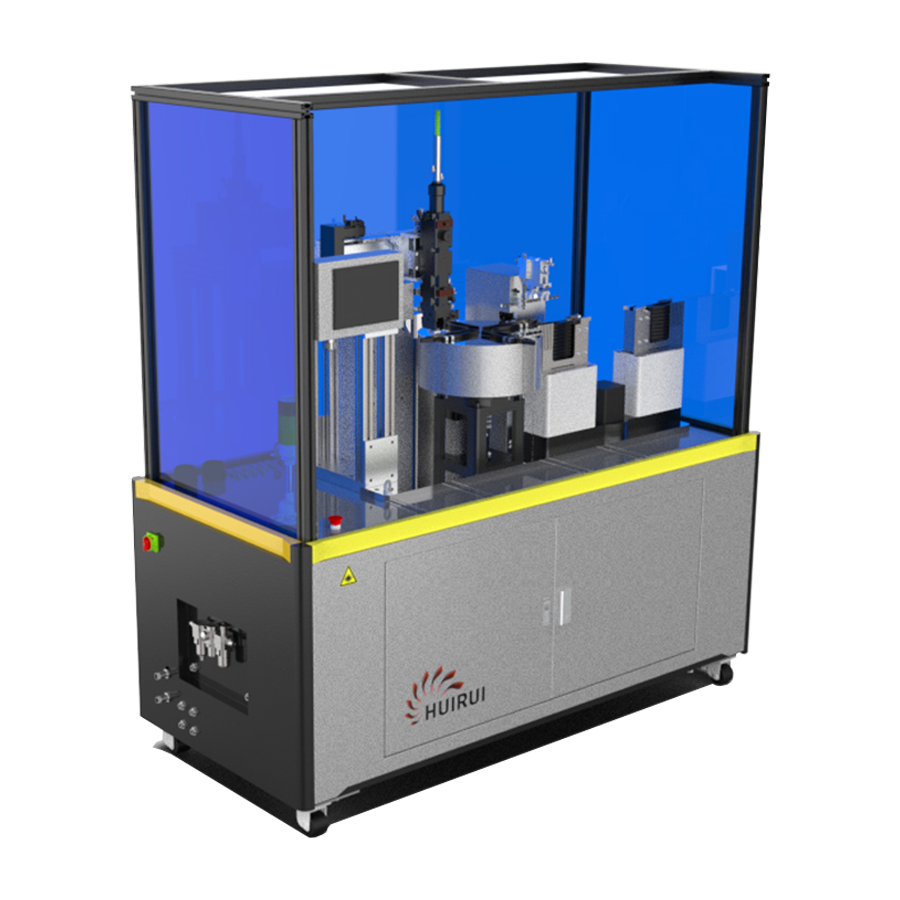

Flexible Configuration and Expansion

Easily integrates with other main control systems to enable synchronized operation. Offers customizable carrier gas volume and speed settings to meet diverse user requirements for different industrial processes. -

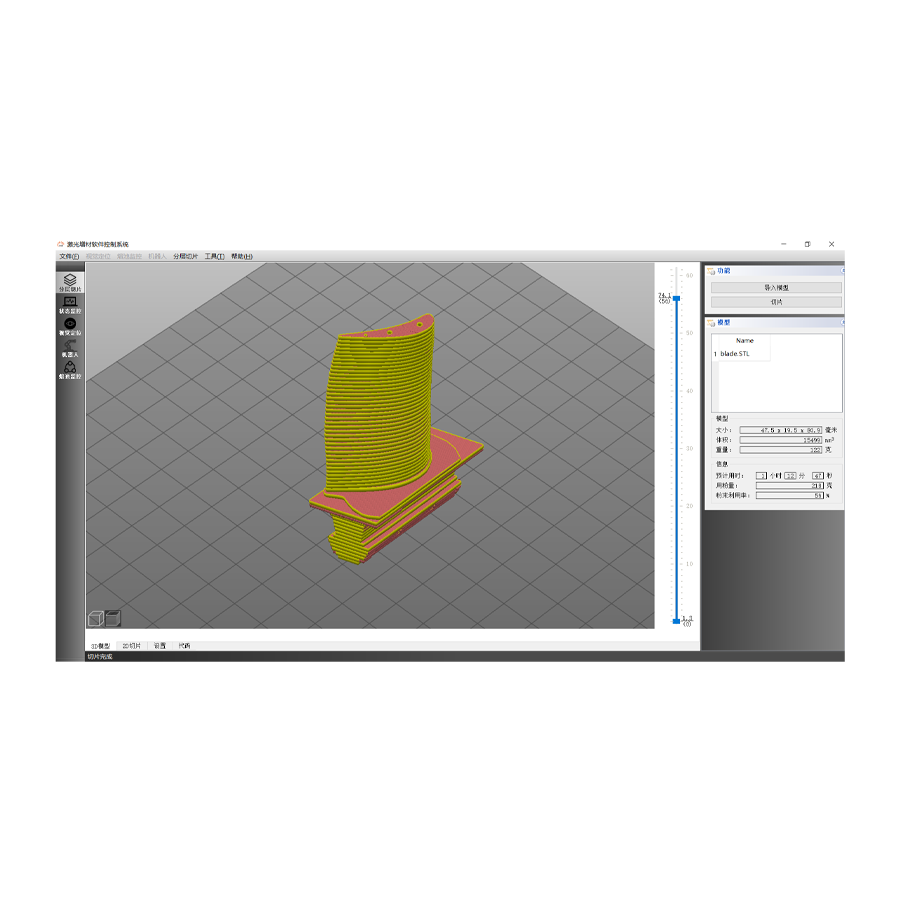

Precision Control and Automated Monitoring

Through electromagnetic vibration control, the system achieves precise powder transfer from the hopper to the vibrating trough and then to the outlet. With positive-pressure air assistance, the powder is delivered steadily into the pipeline. The fully automated process eliminates manual intervention, enhancing continuity and ensuring stable, high-quality production.

| Parameter | Specification |

|---|---|

| Product Model | HR-PFNM-L |

| Powder Feed Rate | 0.1 – 300 g/min (Non-metallic Powder) |

| Applicable Particle Size | 5 – 800 μm |

| Powder Feed Rate Error | ≤ 3% |

| Air Pressure | 0.2 – 0.5 MPa |

| Gas Flow Rate | 3 – 50 L/min (Optional) |

| Heating Temperature | N/A (Can be optionally configured) |

| Single Pass Capacity | 22 L |

| Optional Functions | Automatic Uninterrupted Powder Feeding; Real-time Weighing Function |

| Drive Motor | Brushless DC Motor |

| Remote Control | IO / AI / Modbus TCP / Profinet |

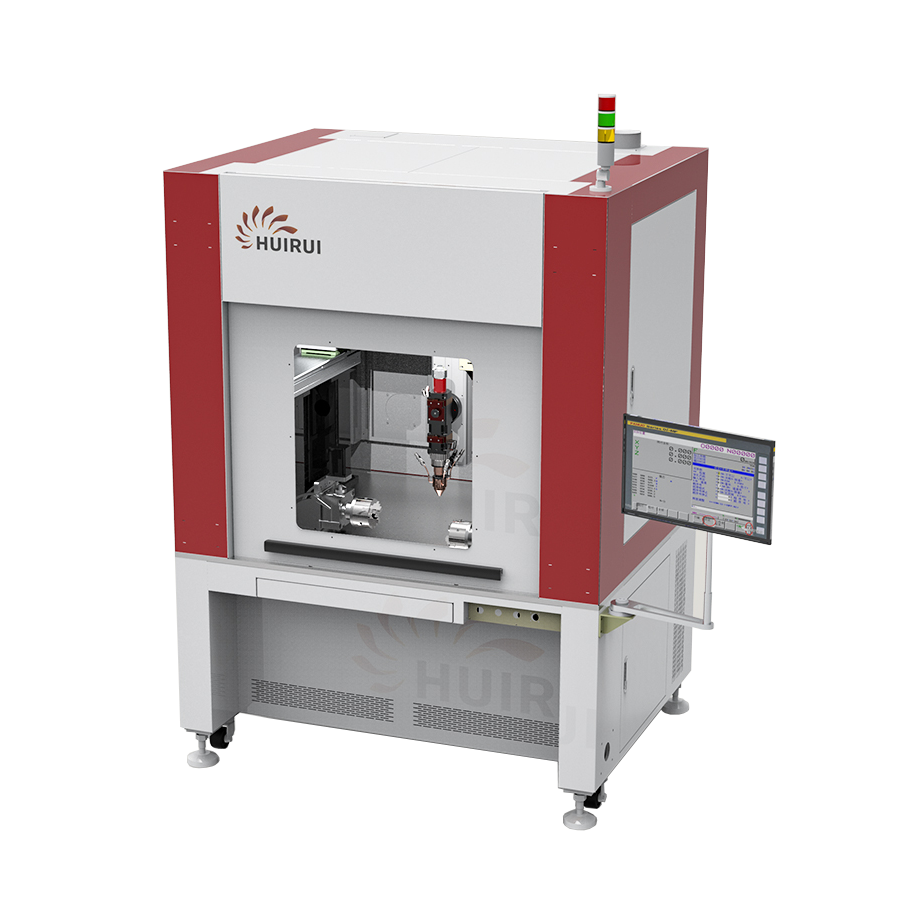

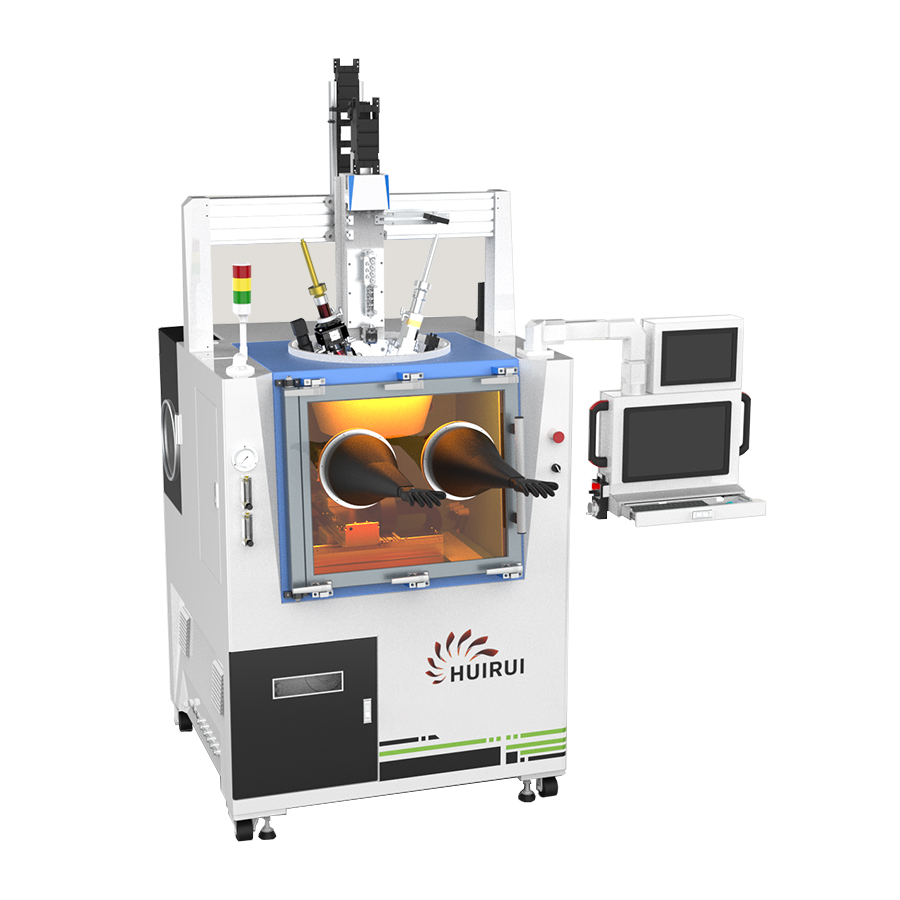

Related products

HUIRUI only makes the best products in this industry