Electromagnetic Disc-Type Powder Feeder

get a free quotePresentation of the equipment's characteristics

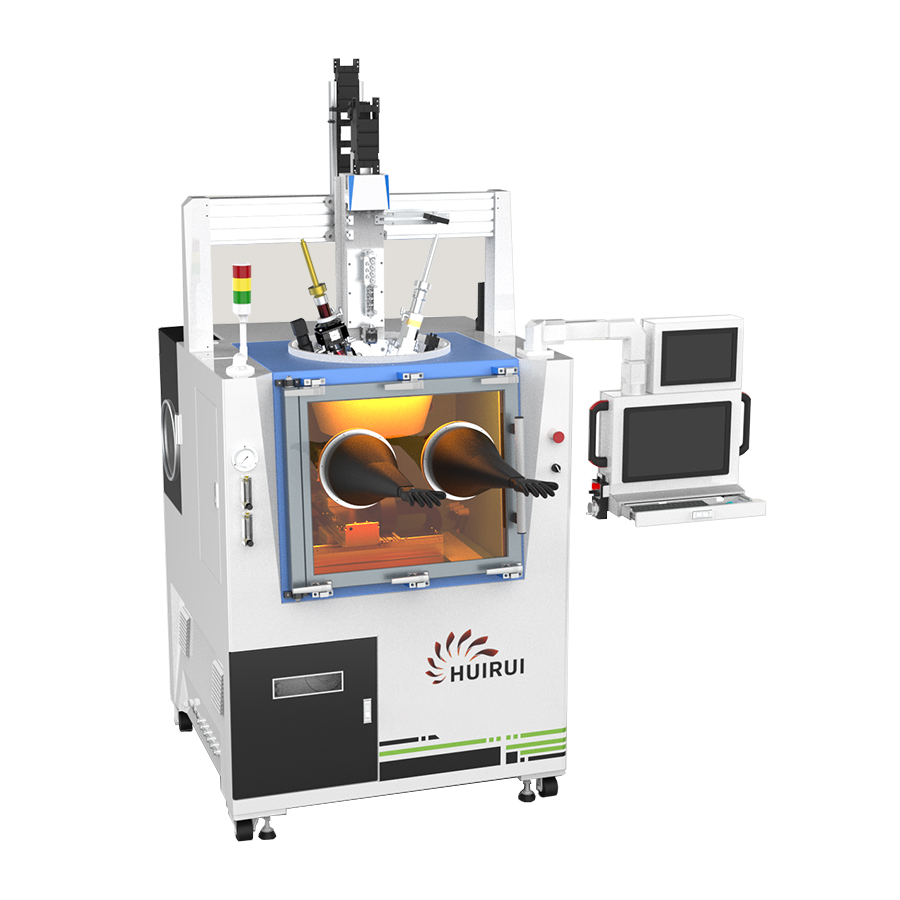

Equipment Introduction

Electromagnetic Disc-Type Powder Feeder

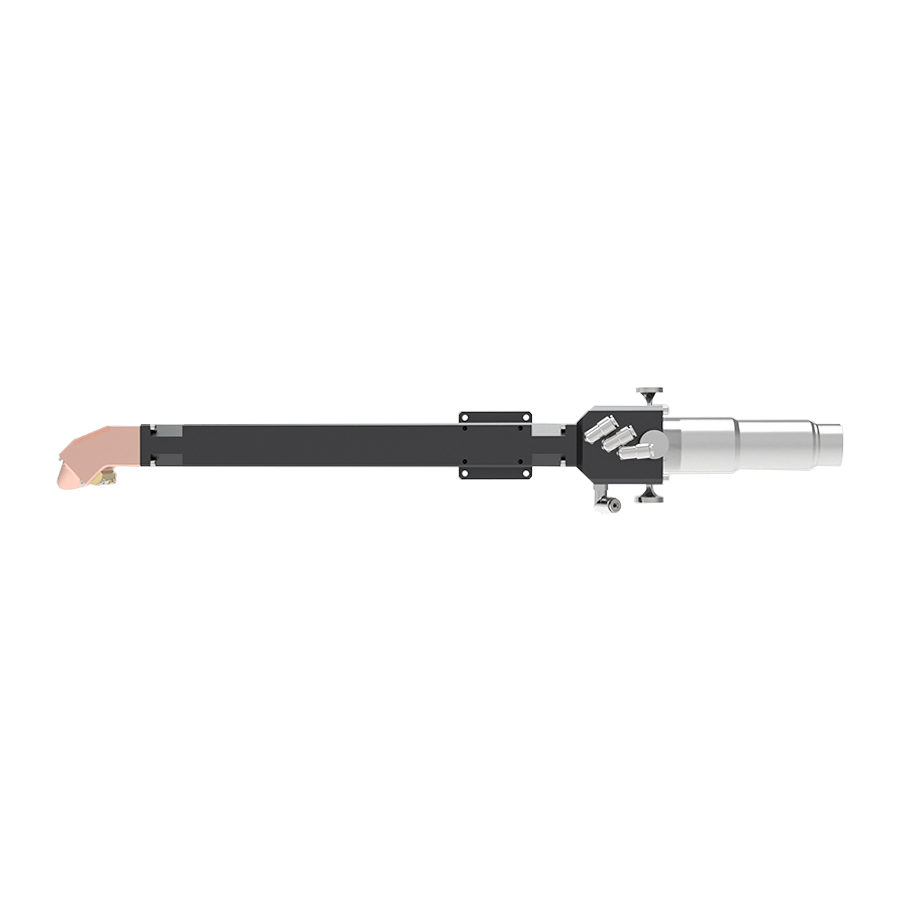

The Electromagnetic Disc-Type Powder Feeder features an innovative circular electromagnetic vibration technology that drives powder in a spiral upward motion. Powered by precise electromagnetic force, the powder is conveyed through a sealed chamber, ensuring long-distance, stable, and leak-free delivery.

Its extended spiral pathway and electromagnetic vibration de-agglomeration function ensure uniform powder flow, effectively preventing clumping or clogging. This guarantees continuous, stable, and high-precision powder output at the discharge end, meeting the stringent requirements of modern industrial processes.

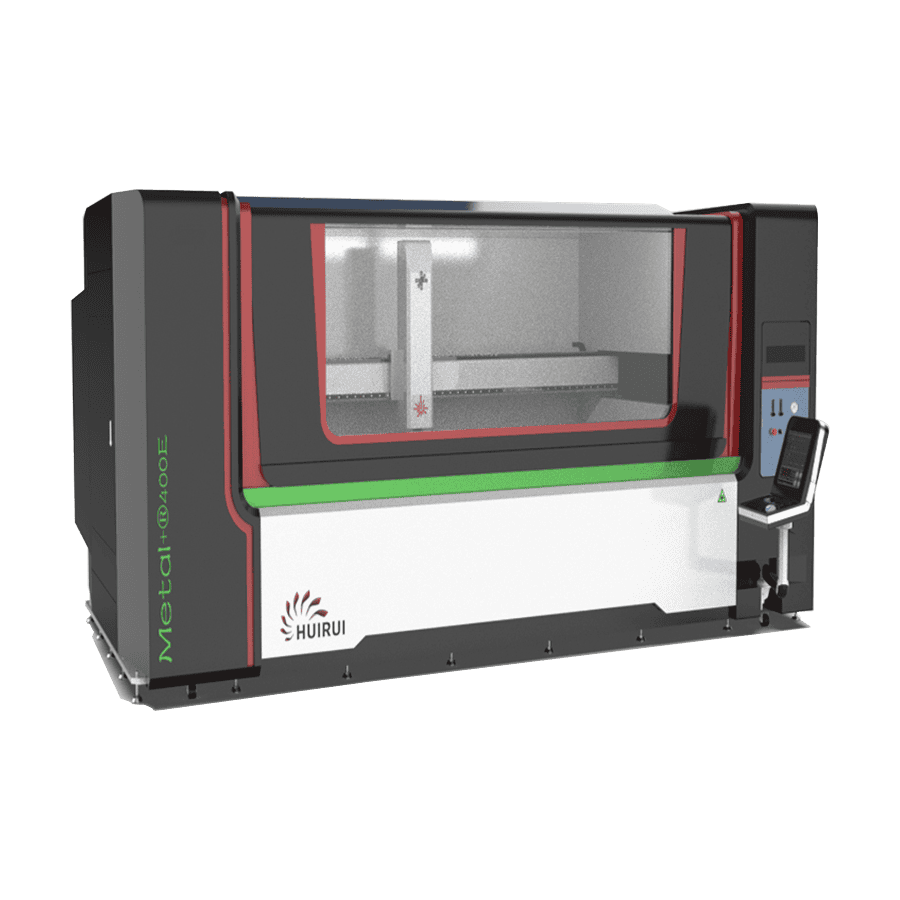

Efficient Spiral Feeding with Sealed Structure for Maximum Stability and Safety

The feeder’s spiral transmission system enhances powder flow efficiency, while the fully enclosed design provides superior protection against leakage and contamination. It is ideal for industries requiring precision powder handling, such as laser cladding, additive manufacturing, coating, and advanced materials processing.

Equipment Advantages

Electromagnetic Disc-Type Powder Feeder

-

Strong Adaptability

Specifically designed for fine, non-metallic, synthetic, and crystalline powders, this system overcomes the material limitations of traditional powder feeders, making it suitable for a wide range of industrial applications. -

High-Efficiency Spiral Feeding

The circular electromagnetic vibration technology drives powder in a spiral upward motion, optimizing the delivery path, reducing powder buildup and dust, and ensuring efficient and orderly feeding throughout operation. -

Long-Distance Stable Transmission

The sealed chamber design effectively prevents powder contamination and leakage during long-distance conveying, ensuring safe, stable, and clean powder transport. -

Precise and Uniform Powder Output

With an extended delivery path and dual electromagnetic de-agglomeration mechanism, the feeder ensures consistent powder flow without fluctuation, significantly improving process stability and precision. -

Anti-Clogging and De-Agglomeration Design

The real-time electromagnetic vibration system separates agglomerated powder, minimizing clogging risks, extending maintenance intervals, and reducing operational costs for long-term reliability.

| Parameter | Specification |

|---|---|

| Product Model | HR-PFNM-D |

| Powder Feed Rate | 0.1 – 90 g/min (Non-metallic Powder) |

| Applicable Particle Size | 5 – 800 μm |

| Powder Feed Rate Error | ≤ 3% |

| Air Pressure | 0.2 – 0.7 MPa |

| Gas Flow Rate | 3 – 50 L/min (Optional) |

| Heating Temperature | N/A (Can be optionally configured) |

| Single Pass Capacity | 1.5 L |

| Optional Functions | Automatic Uninterrupted Powder Feeding; Real-time Weighing Function |

| Drive Motor | N/A |

| Remote Control | IO / AI / Modbus TCP / Profinet |

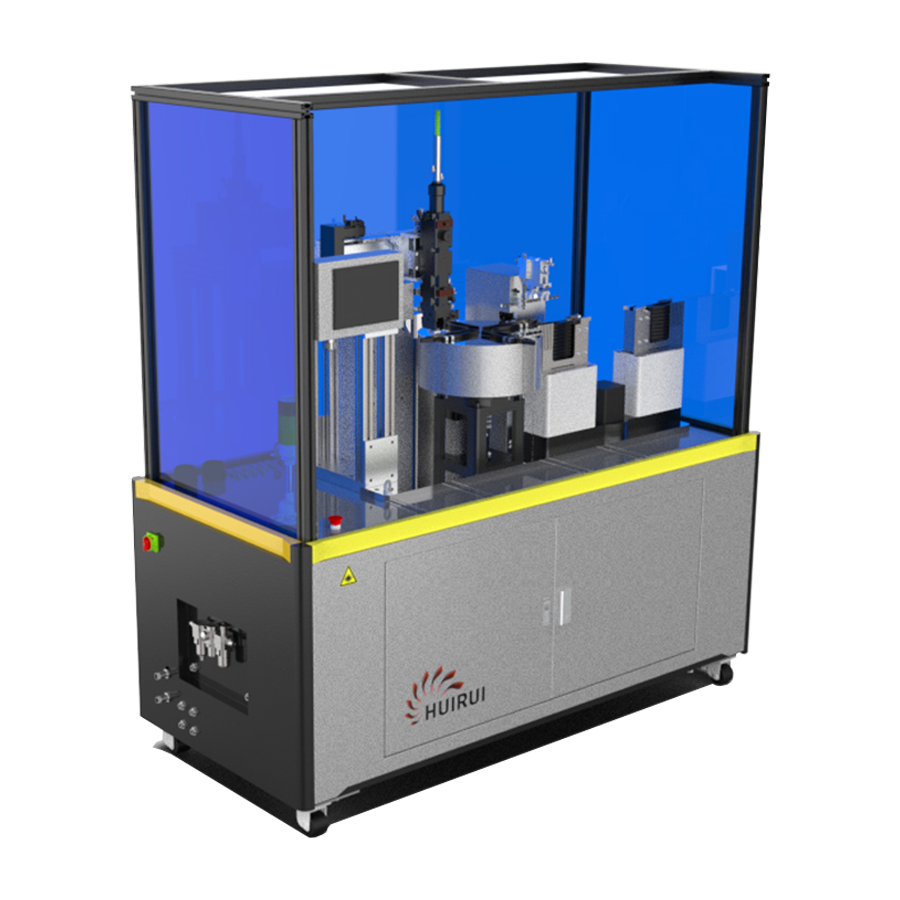

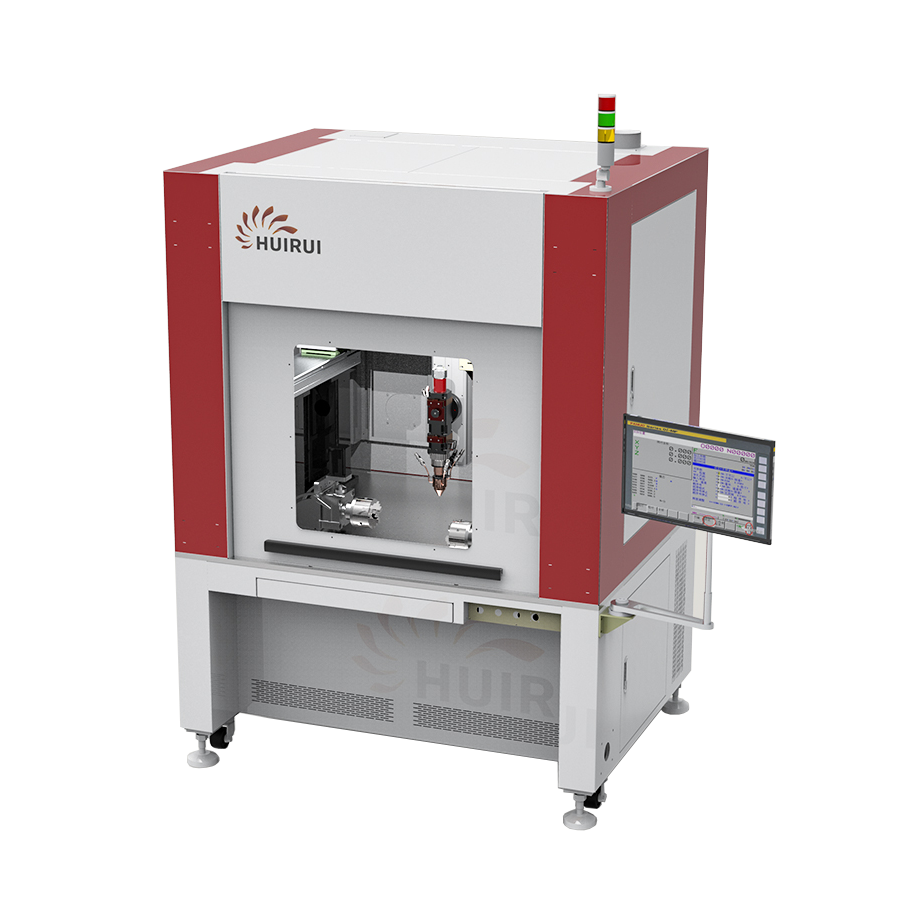

Related products

HUIRUI only makes the best products in this industry