Blind hole laser cladding head

get a free quotePresentation of the equipment's characteristics

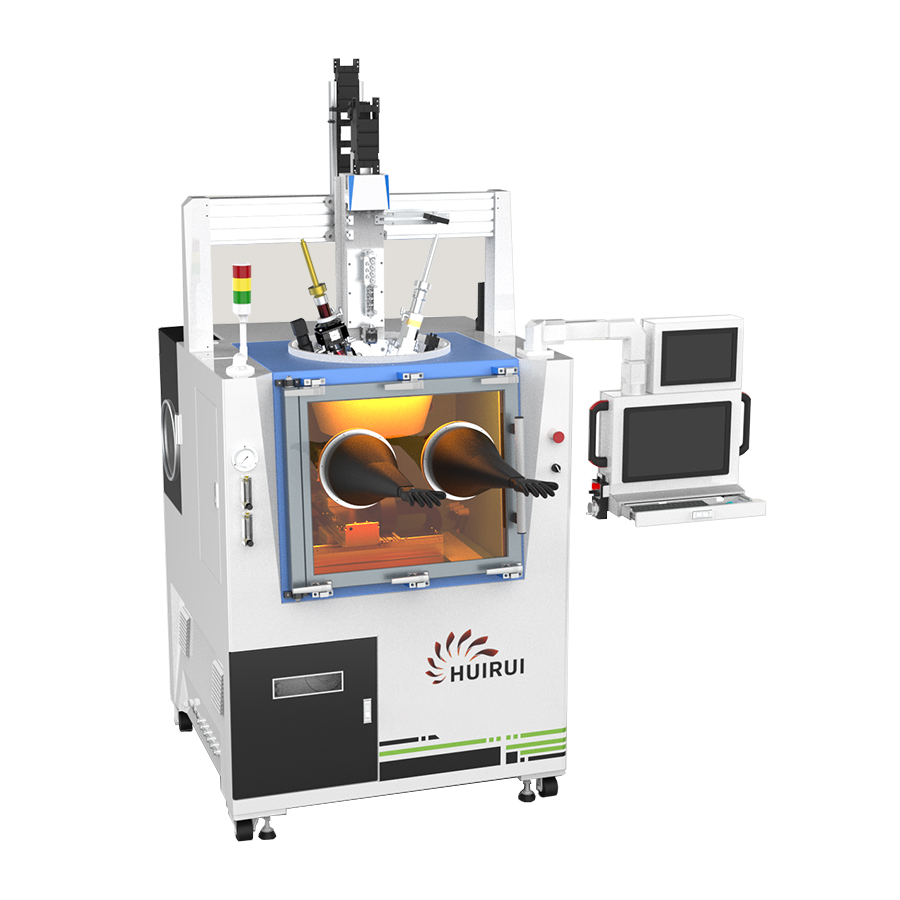

Equipment Introduction

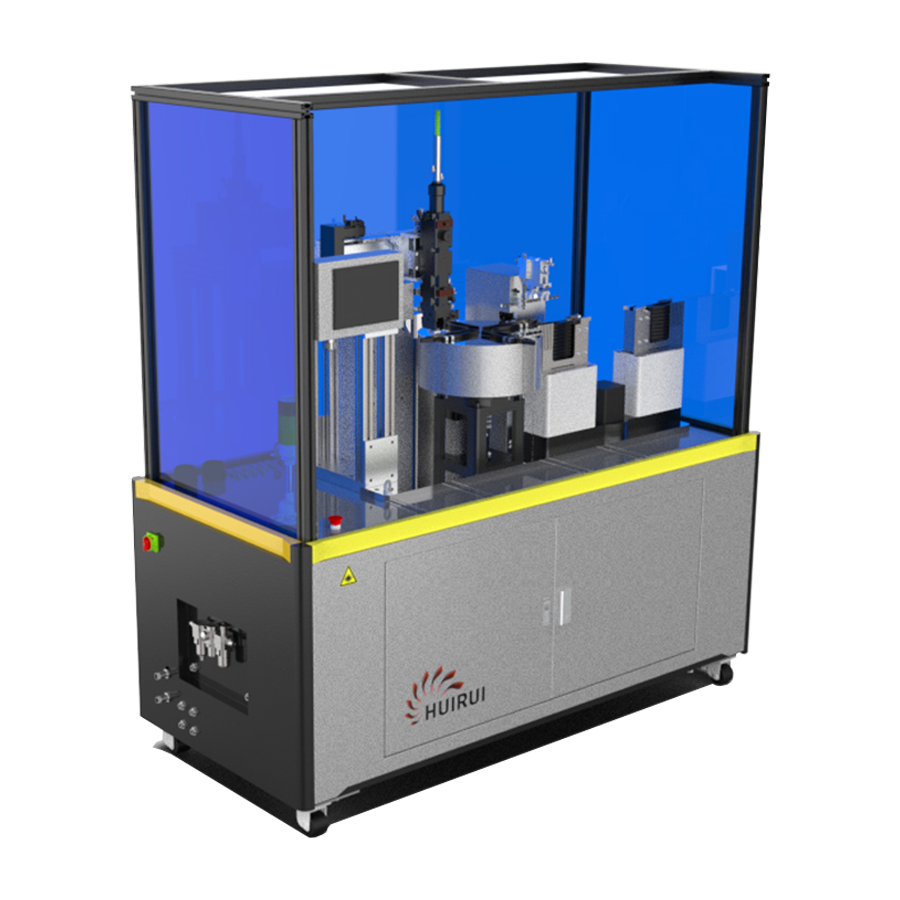

Huirui-Laser Blind Hole Laser Cladding Head

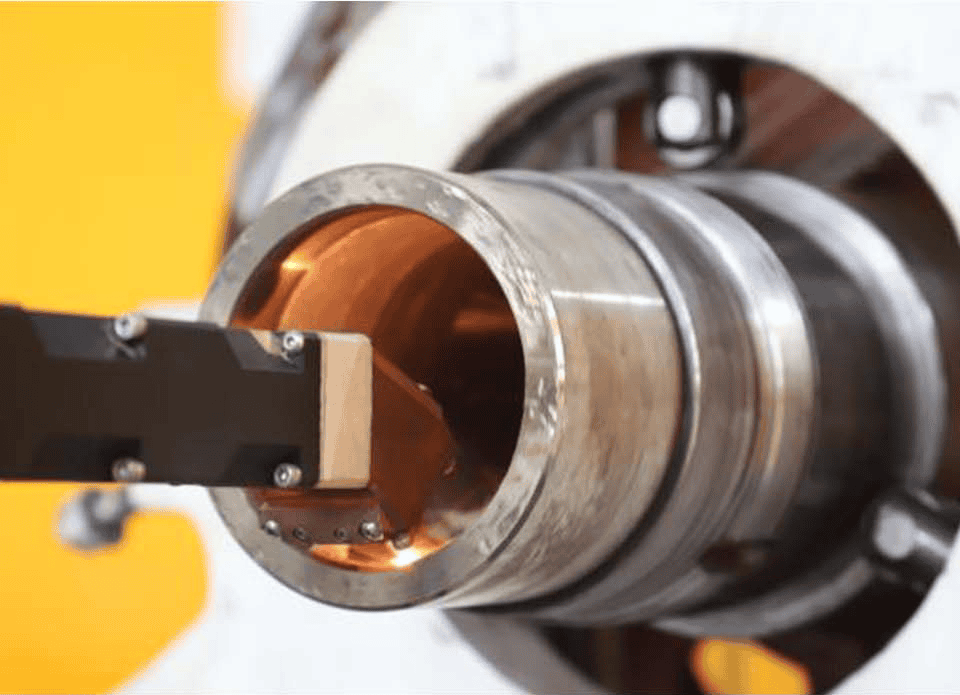

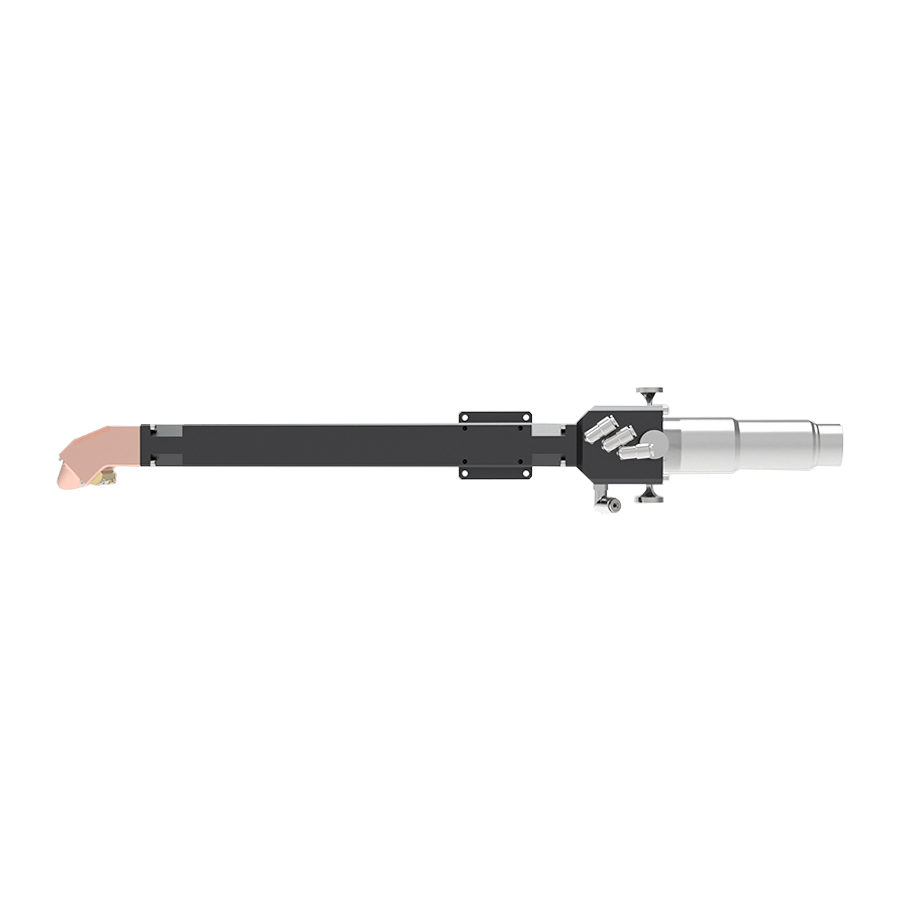

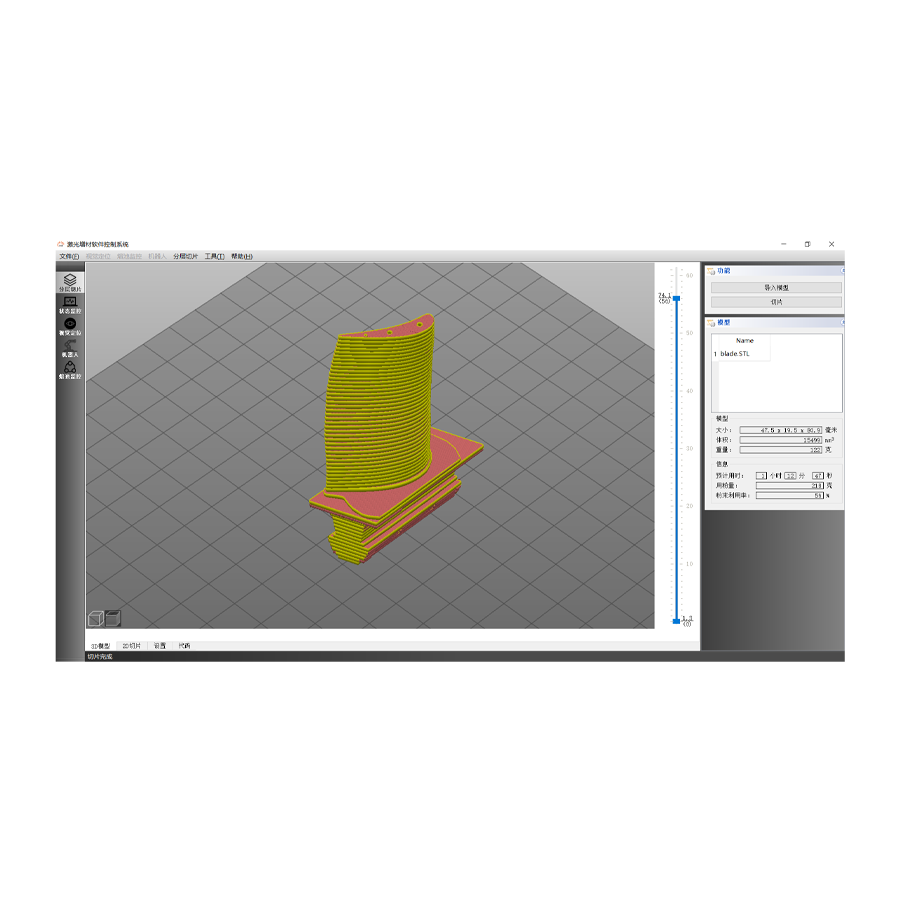

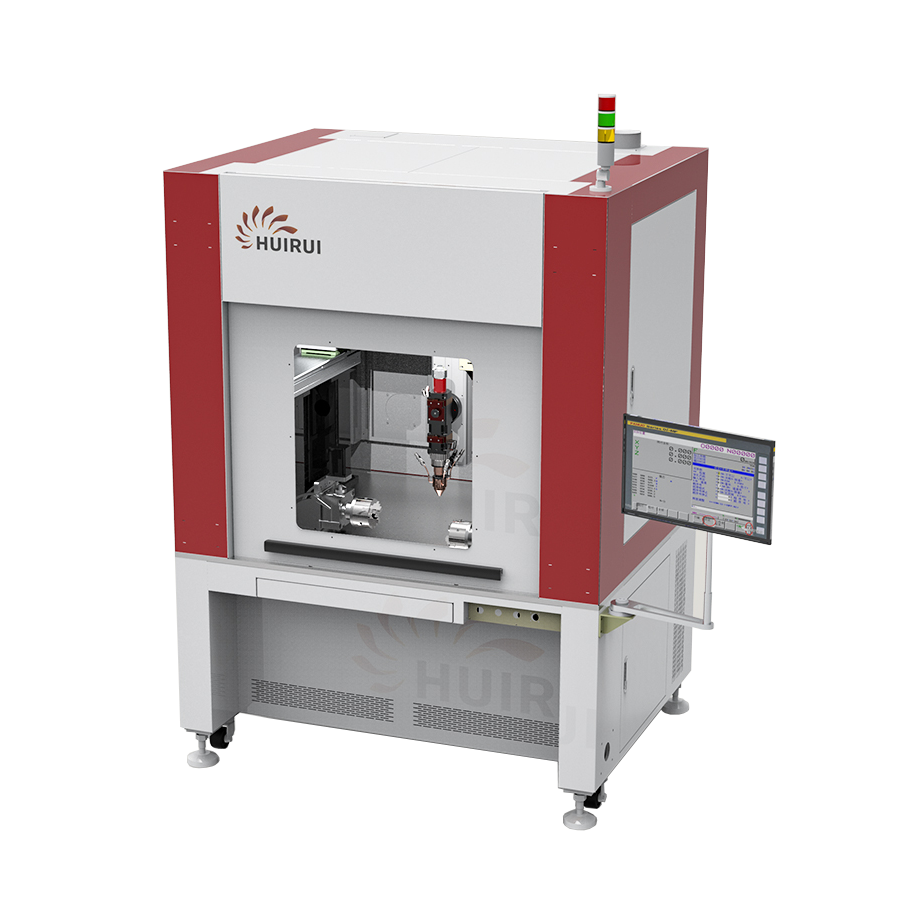

The Huirui-Laser independently developed Blind Hole Laser Cladding Head is designed to solve the long-standing challenge of processing the bottom area of blind holes—an issue conventional internal cladding heads face due to 90° beam reflection limitations. This innovative system utilizes reflective mirrors and optical deflectors to bend the laser path, significantly reducing the head height and improving spatial adaptability. As a result, it can efficiently complete full-area blind hole cladding with precision and stability.

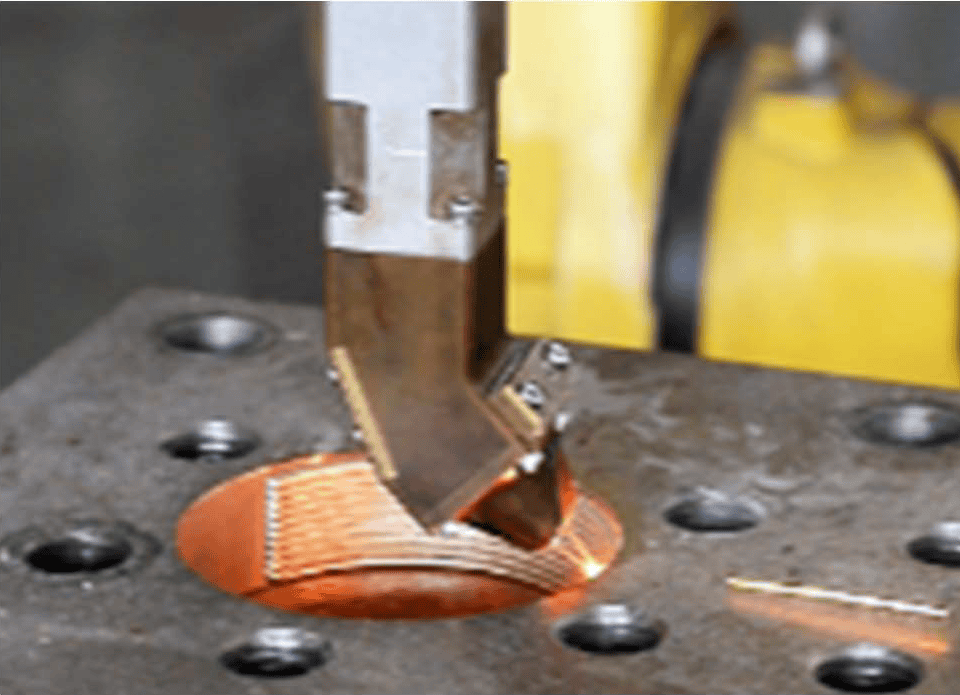

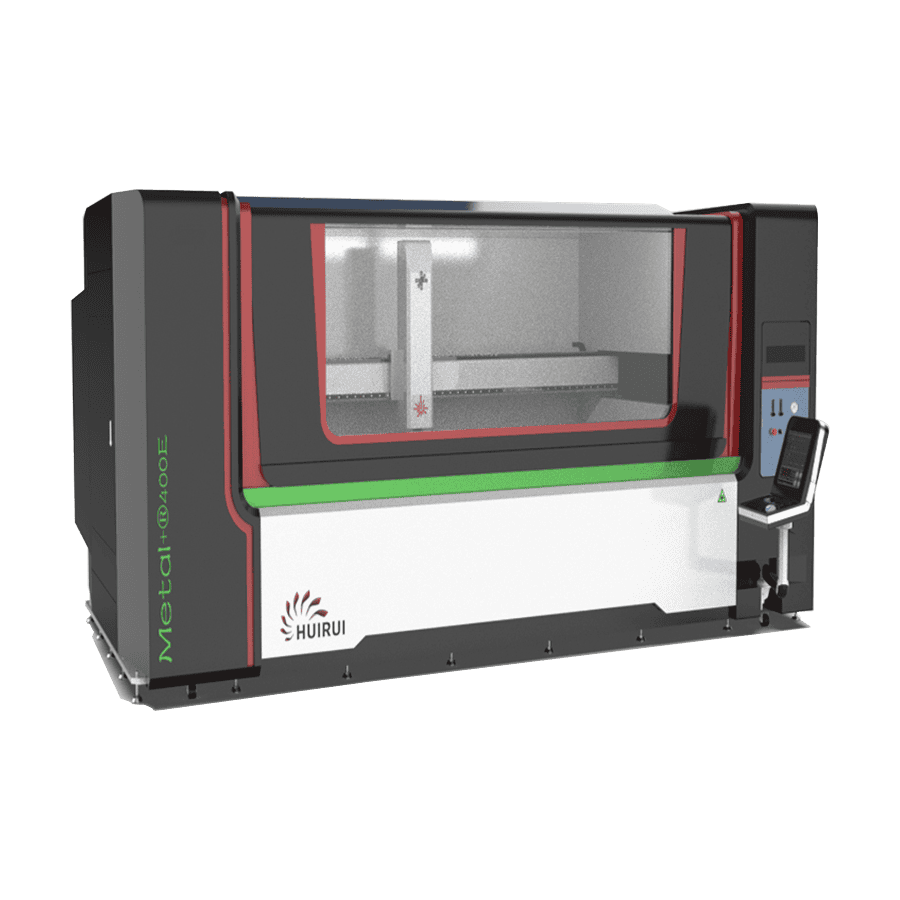

Featuring multi-interface compatibility, this cladding head can be flexibly connected with a wide range of fiber and semiconductor lasers. It has already been successfully applied in coal mining machinery, petrochemical engineering, and shipbuilding industries, providing customers with high-efficiency, reliable internal surface strengthening and repair solutions.

Under standard working conditions (cladding thickness of 1 mm), the equipment achieves a cladding efficiency of up to 0.2 m²/h and supports laser power up to 4 kW. The minimum applicable bore diameter is 80 mm. Its modular design allows the use of customized extension rods, with a single-side cladding length of up to 1200 mm, meeting diverse processing depth requirements and expanding its application range.

Structurally, the system adopts a fully sealed design integrating optical, water, gas, and powder circuits into a single compact body. The innovative plug-in protective lens module allows for easy replacement and maintenance while maintaining a dust-free optical path. This design ensures complete and uniform cladding of blind hole interiors, solving the limitations of traditional systems that cannot reach specific deep or narrow regions.

Today, the Huirui Blind Hole Laser Cladding Head has been successfully implemented across multiple key industrial sectors—including coal mining equipment, petrochemical plants, and marine engineering—helping enterprises reduce maintenance costs, extend component service life, and enhance overall operational reliability.

Equipment Advantages

-

Strong Compatibility and Adaptability

Built with laser-grade modular optical design, the system supports up to 4 kW fiber and semiconductor lasers, ensuring seamless integration with mainstream industrial laser brands. -

Adaptive Depth Adjustment

Features a modular extension rod system (0–1200 mm freely configurable) with ±0.1 mm cladding depth accuracy, capable of processing blind holes as small as 80 mm in diameter. -

Fully Sealed Four-in-One Integration

The optical, water, gas, and powder circuits are fully integrated inside the cladding head, forming a dustproof and oil-resistant sealed structure that ensures stable operation and easy maintenance under harsh industrial conditions. -

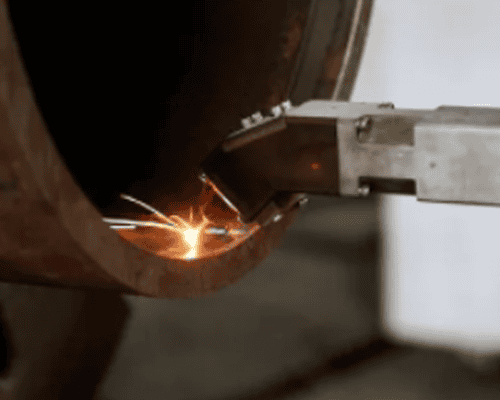

45° Inclined Blind Hole Processing Technology

Utilizes a synchronized deflection design for powder flow and laser beam, effectively resolving bottom coverage challenges in blind holes. Compatible with iron-based, nickel-based, and copper-based alloy coatings, delivering high-quality metallurgical bonding. -

Plug-and-Play Protective Lens Design

Equipped with a removable protective lens module for fast replacement and cleaning, minimizing downtime and significantly improving operational efficiency.

| Parameter | Specification | Parameter | Specification |

|---|---|---|---|

| Product Model | D80M | Cladding Efficiency | 0.2 m²/h |

| Applicable Power | 4 kW | Light/Powder Adjustment | Yes |

| Applicable Wavelength | 900-1100 nm | Spot Size | 3-4 mm |

| Fiber Interface | QBH | Temperature Measurement Module | Optional |

| Minimum Applicable Aperture | 80 mm | Powder Exhaust Module | Optional |

| Standard Depth | 500 mm | Water/Powder Channel | Built-in |

| Maximum Depth | 1000 mm | Protective Gas | Yes |

| Number of Protective Windows | 1 | Powder Feeding Method | Two-Point Powder Feeding |

| Collimation Adjustment | ±2 mm | Capable of Processing Blind Holes | Yes |

Related products

HUIRUI only makes the best products in this industry