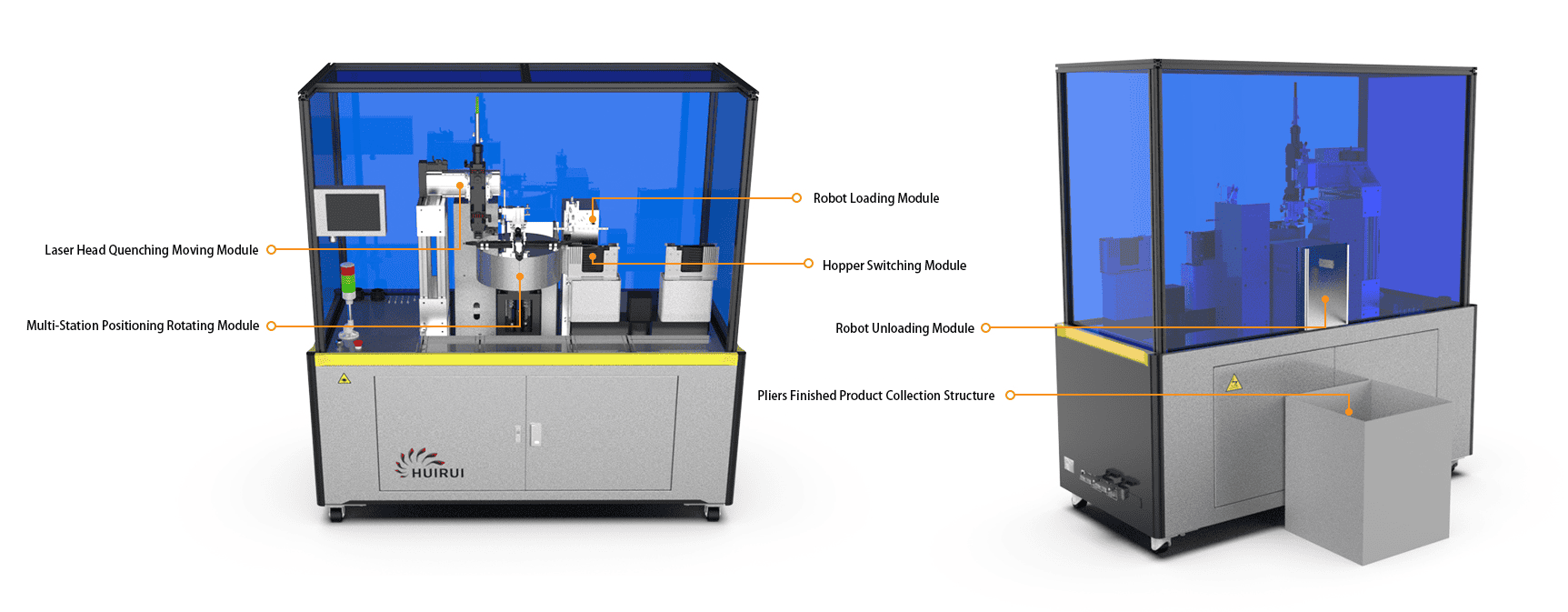

Automated Laser Hardening System for Pliers Blades

get a free quotePresentation of the equipment's characteristics

Laser Hardening Equipment Series | Automated Laser Hardening System for Pliers Blades

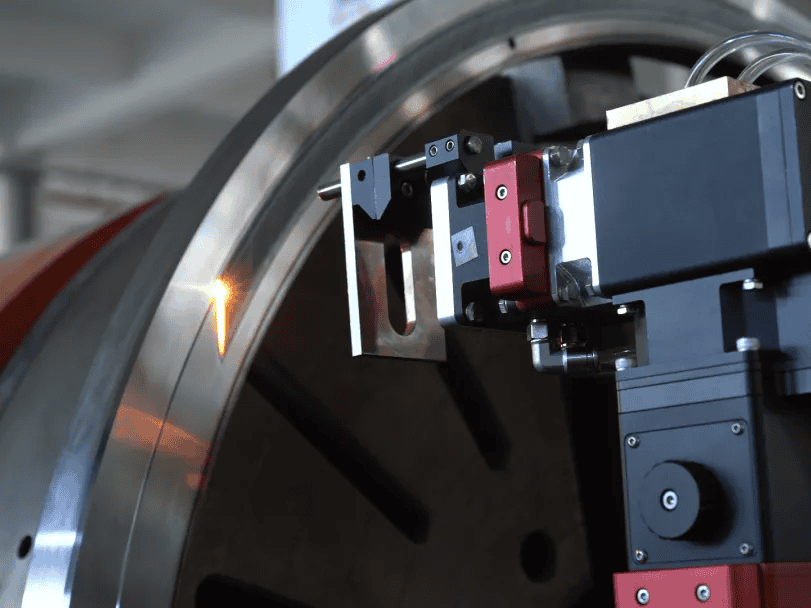

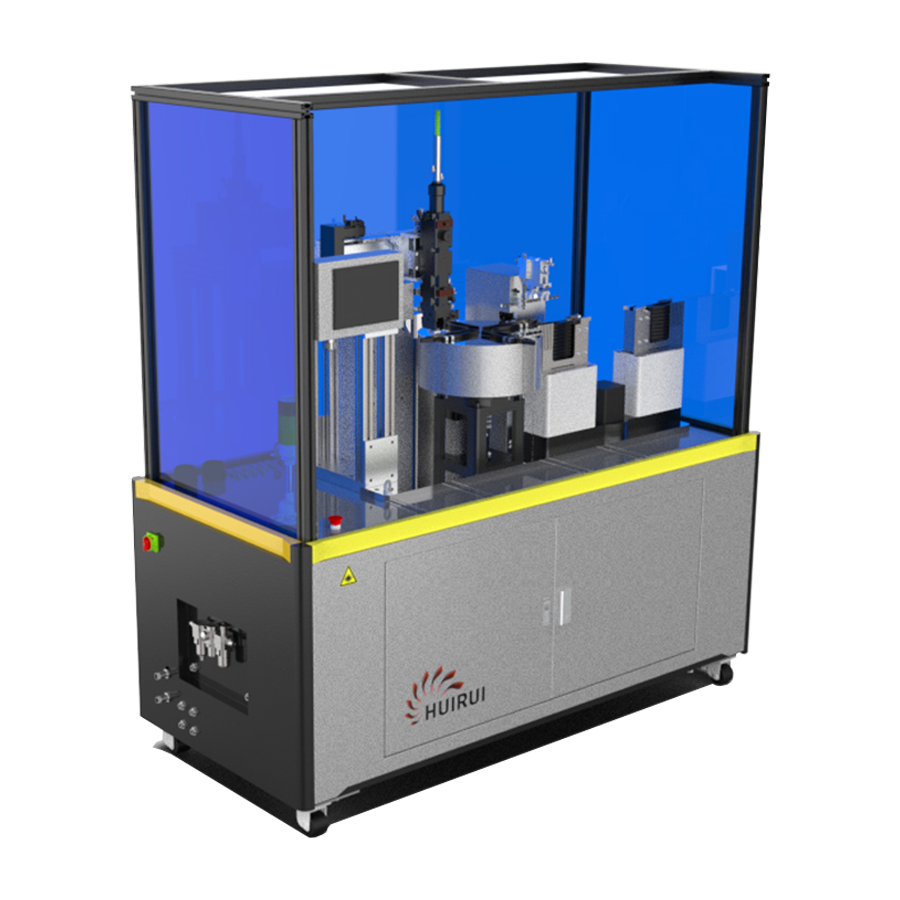

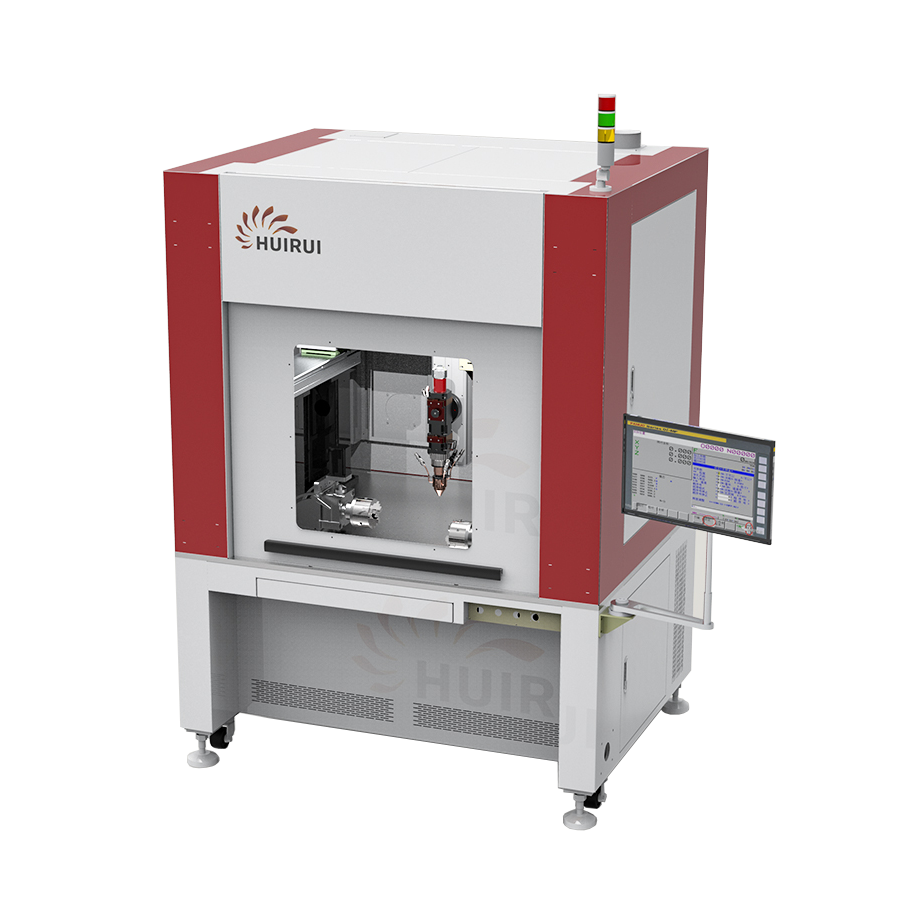

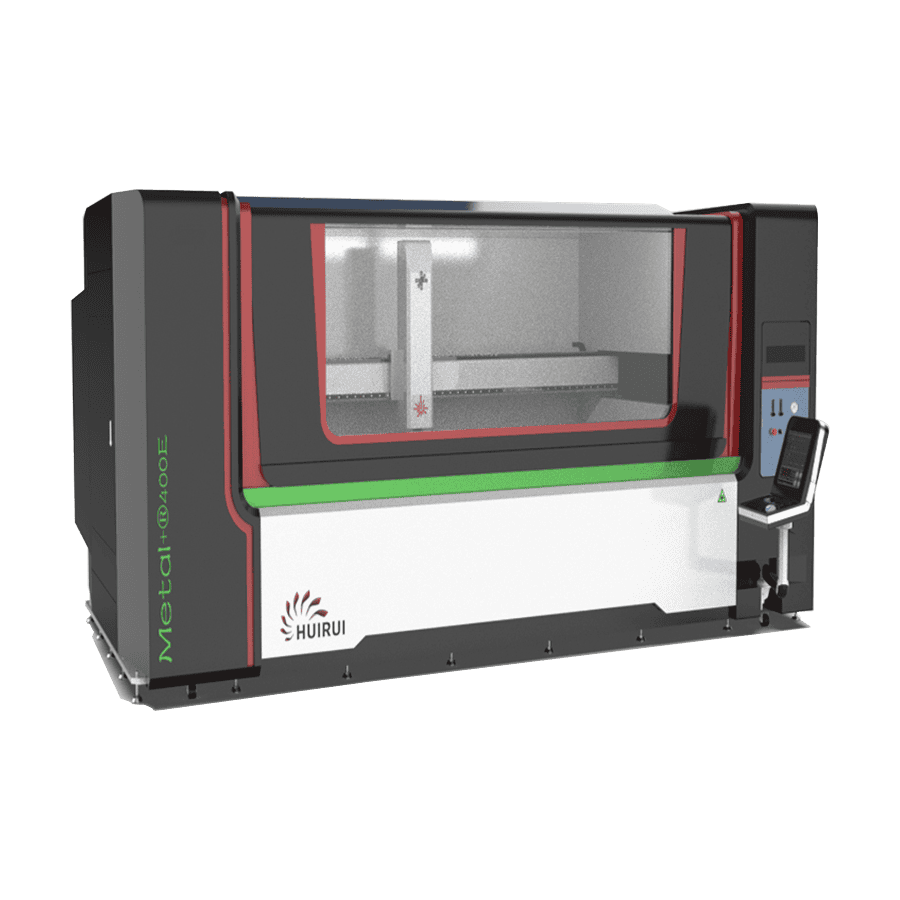

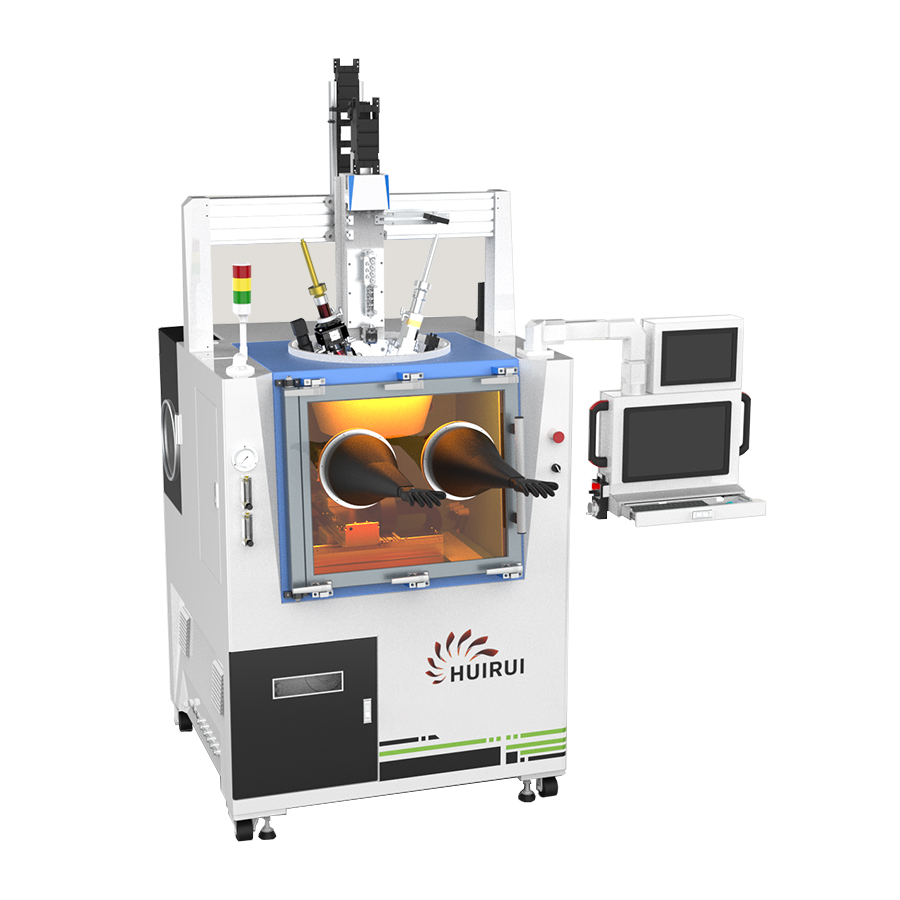

This advanced laser hardening system utilizes cutting-edge lasers and industrial robots to achieve multi-axis synchronized automation processing. It can also be customized based on customer requirements, with tailored tooling and material handling systems for automatic laser hardening and loading/unloading functions. The laser hardening process offers high power density, rapid cooling, and eliminates the need for cooling media. The hardened layer is uniform, offering higher hardness with minimal workpiece deformation. It is easy to control the heating depth and path, making it ideal for surface treatment of high-precision components. Laser hardening is gradually replacing traditional induction hardening and chemical heat treatment processes, becoming the preferred choice in industrial applications.

The system is composed of advanced lasers, industrial robots, and control systems, forming a multi-axis automated laser processing system. Customized tooling and loading/unloading devices are developed based on customer parts and process requirements. It enables the automation of laser hardening, as well as loading and unloading functions.

Advantages of Laser Hardening Technology

Laser hardening is a process that uses a laser to heat the surface of the material above its austenite transformation point. The material then cools on its own, transforming austenite into martensite, thereby hardening the surface. Laser hardening features high power density, rapid cooling, and does not require cooling media like water or oil. Compared to induction hardening, flame hardening, and carburizing processes, laser hardening produces a uniform hardened layer with higher hardness, minimal workpiece deformation, and precise control over heating depth and path. It is easier to automate and does not require designing specific induction coils for different part sizes, as needed with induction hardening. Moreover, laser hardening does not face limitations from furnace size when working with large parts, unlike carburizing or other chemical heat treatment processes.

As a result, laser hardening is gradually replacing traditional heat treatment methods, including induction hardening and carburizing, across various industrial sectors. Notably, the deformation of workpieces before and after laser hardening is almost negligible, making it particularly suitable for surface treatments of high-precision components.

processed samples

Key Features and Advantages of Laser Hardening Equipment

-

High Power Density and Fast Cooling: Laser hardening offers high power density and rapid cooling, eliminating the need for cooling media such as water or oil.

-

Uniform Hardened Layer with Higher Hardness: Compared to induction hardening, flame hardening, and carburizing processes, laser hardening produces a more uniform hardened layer with higher hardness (typically 1-3 HRC higher than induction hardening).

-

Minimal Workpiece Deformation: Laser hardening causes minimal deformation of the workpiece. The heating depth and path are easy to control, making automation easier. Unlike induction hardening, there is no need to design custom induction coils for different part sizes. Additionally, there are no size limitations for large parts, unlike carburizing or other chemical heat treatments.

-

Laser Hardening Replacing Traditional Methods: Laser hardening is gradually replacing traditional processes like induction hardening and chemical heat treatment. Importantly, the deformation of workpieces before and after laser hardening is negligible, making it particularly suitable for surface treatment of high-precision components.

| Parameter | Specification |

|---|---|

| Equipment Name | Vise Jaw Automated Laser Quenching Equipment |

| Control System | Closed-loop Motion Control |

| Cycle Time | 6s/piece |

| Laser Type | Fiber / Semiconductor Laser |

| Laser Power | 2-10 kW |

| Chiller | Dual-Temperature, Dual-Control |

| Laser Spot | Line Laser 2x5mm |

| Overall Size | 2x1x2m |

| Power Consumption | < 5 kW |

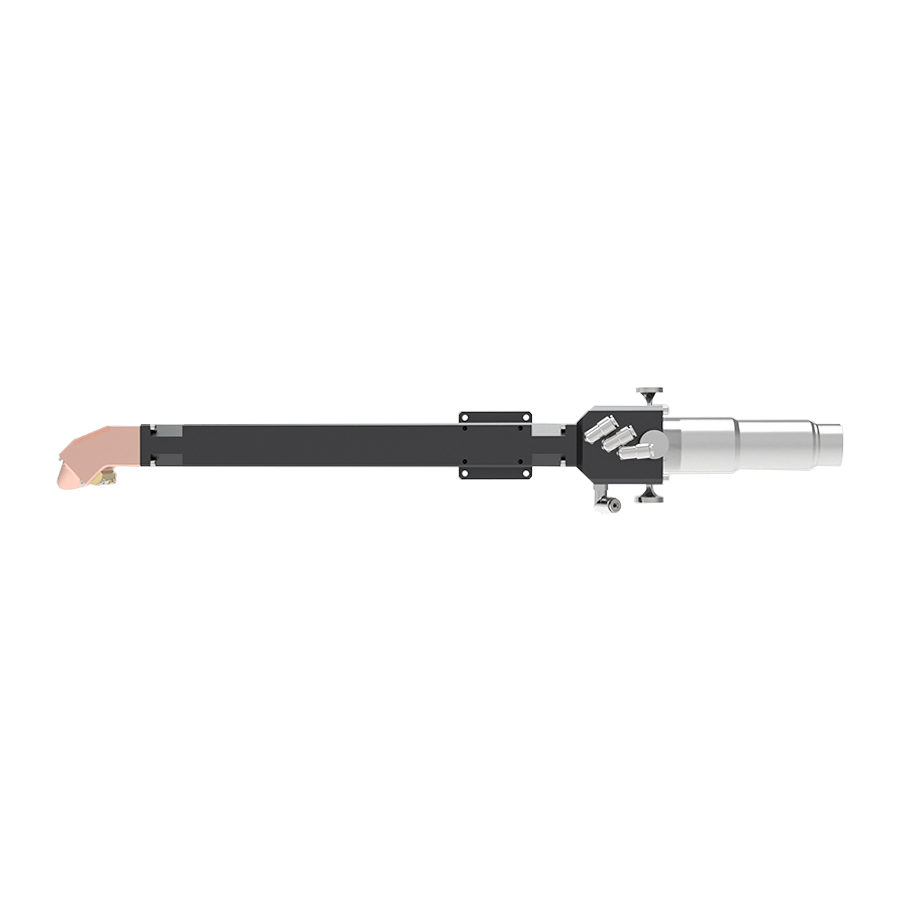

| Laser Head | Straight Plate / Curved Plate Laser Head |

| Positioning Accuracy | ±0.03 mm |

| Spot Shape | Round / Square / Line |

| Spot Size | 0.4~6 mm |

| Expandable Modules | CCD Camera Module and other functional modules |

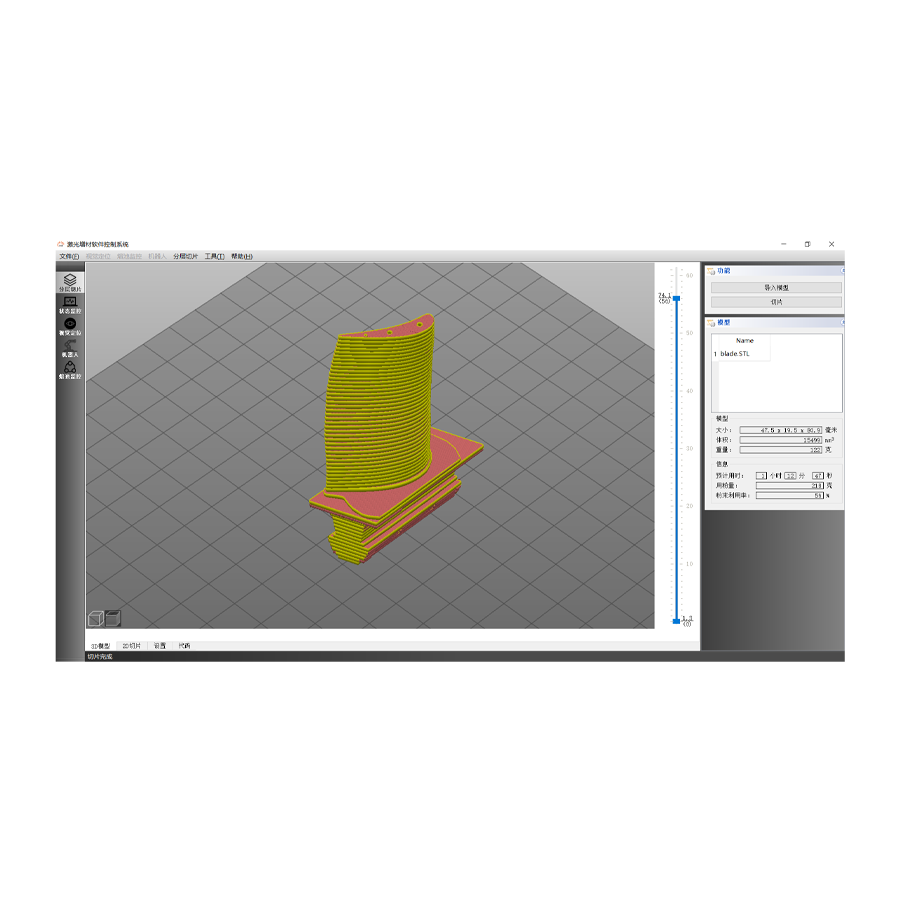

| Software Configuration | Production Monitoring Software, CCD Recognition Software |

Related products

HUIRUI only makes the best products in this industry