Automated Laser Cladding System for Mining Picks

get a free quotePresentation of the equipment's characteristics

Product Overview

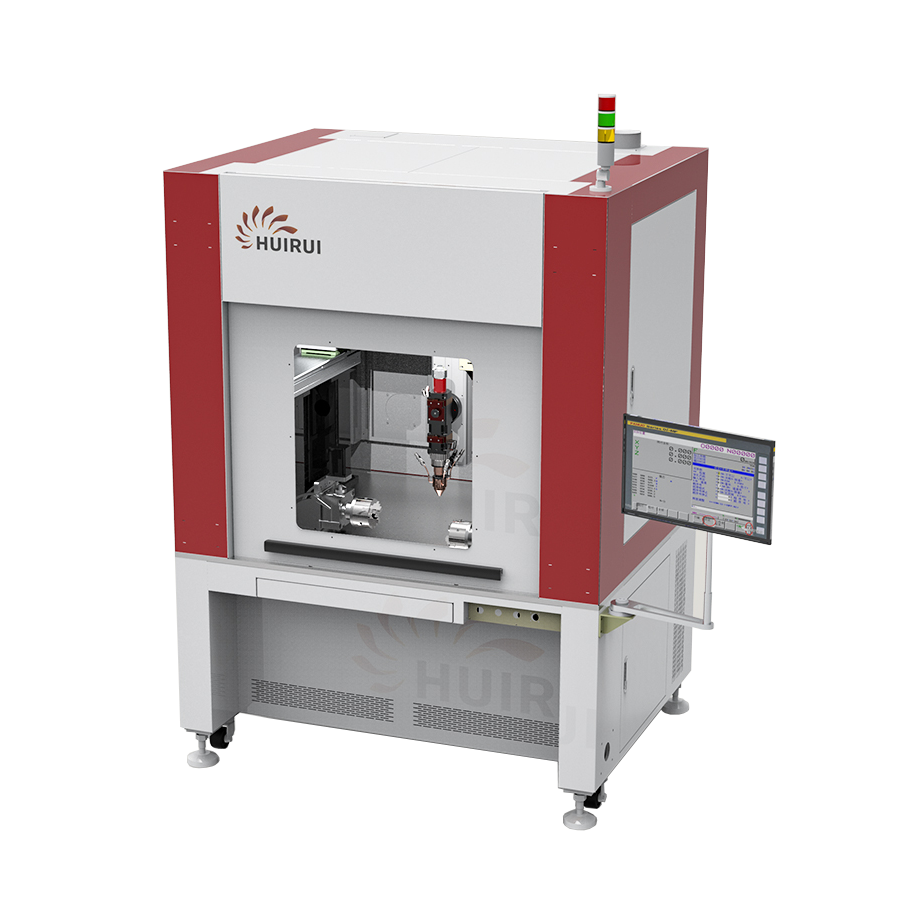

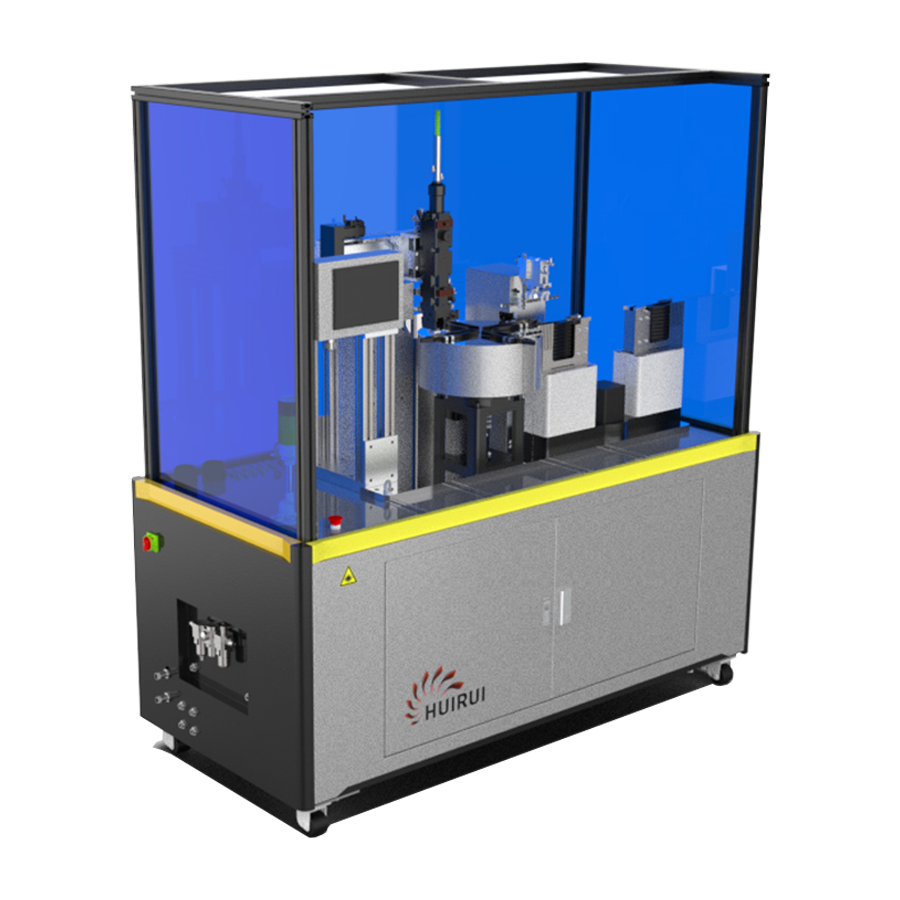

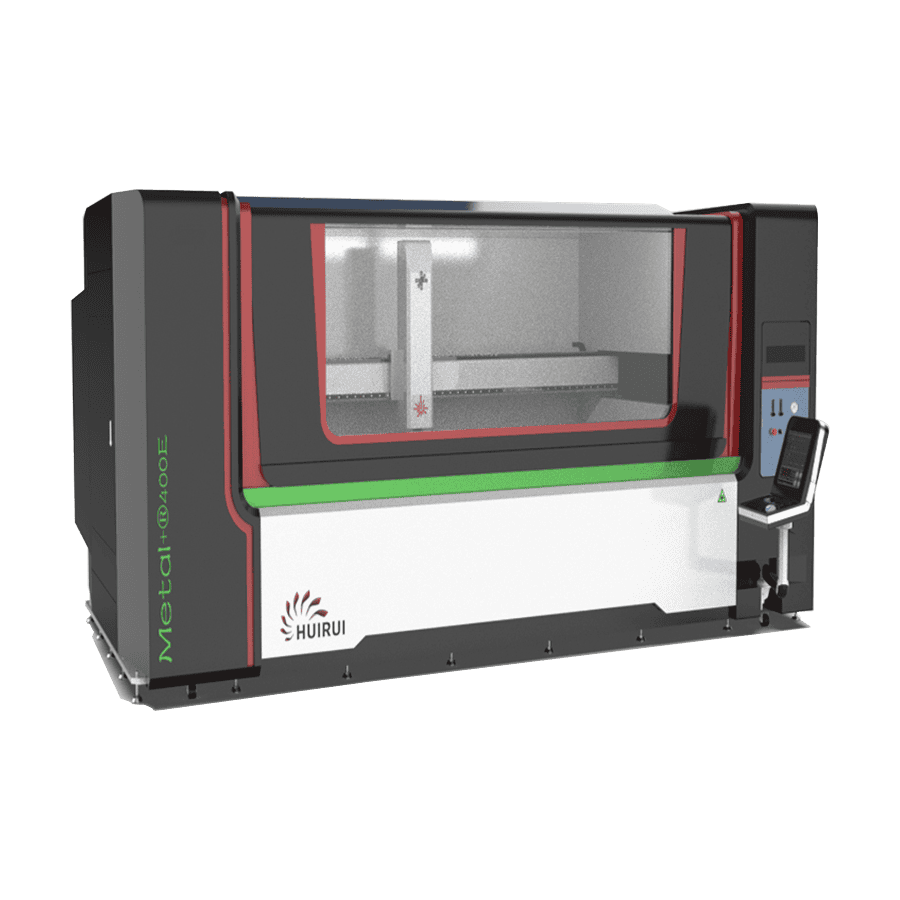

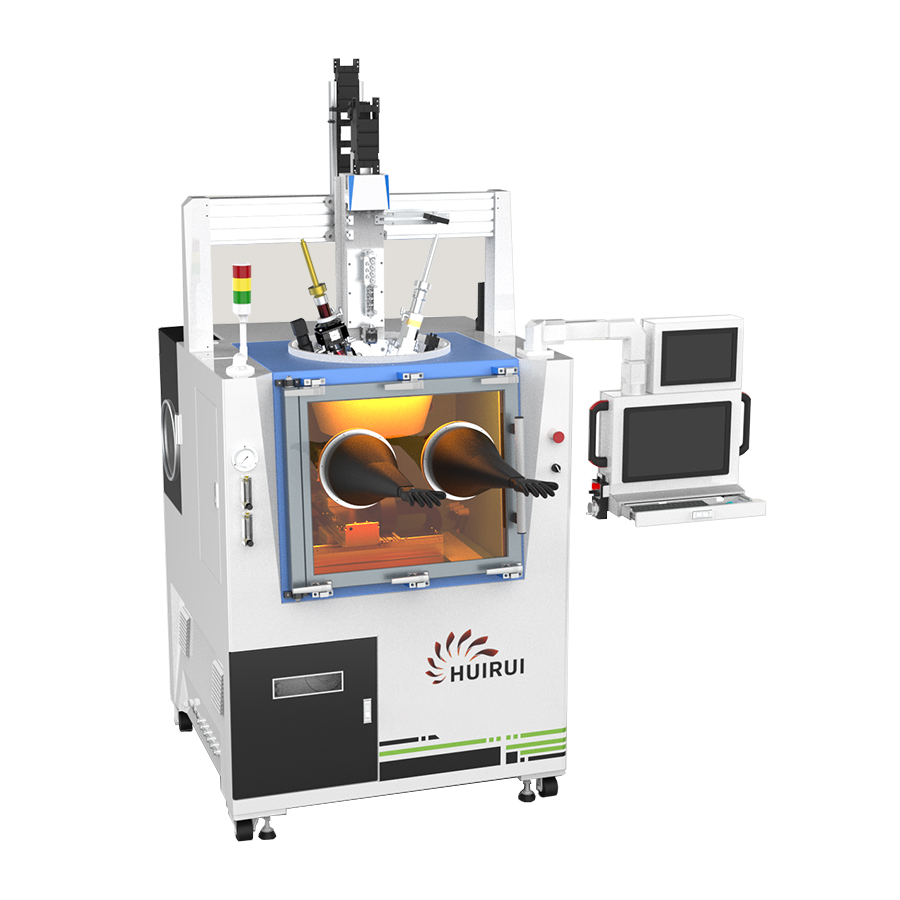

The Huirui-Laser Automated Laser Cladding System is an advanced direct metal additive manufacturing technology developed by Huirui-Laser. It integrates a linear module, two-axis positioner, and automatic loading/unloading system, making it ideal for multi-material additive manufacturing and surface coating enhancement. Designed for metal direct forming and precision repair, this system efficiently processes inert metal powders using direct laser metal deposition (DMD) technology.

Equipped with a highly integrated control module, servo motor drives, and powder feeding nozzles, the system ensures safe operation, precise shape control, and rapid forming. Its open software architecture offers flexibility for parameter adjustments, enabling it to meet the stringent demands of both material research and surface strengthening applications. Overall, this system combines efficiency, flexibility, and precision, making it an ideal solution for materials research and surface enhancement in industries like mining, aerospace, and manufacturing.

Key Features

-

Automated Laser Cladding: Ideal for surface repair and metal part enhancement with precise laser deposition of metal powders.

-

Multi-Material Additive Manufacturing: Supports diverse metal powders, including non-reactive materials for flexible production.

-

Precision Control: Servo motor-driven system ensures accurate shaping and rapid build-up of parts.

-

Integrated System Design: Features linear modules, two-axis positioning, and automated material handling for smooth operation.

-

Open Software Architecture: Customizable control system parameters to meet specific production and research needs.

-

Efficient and Flexible Operation: Designed for metal direct forming and precise repair with quick setup and processing times.

Applications

-

Surface repair and reinforcement of mining picks and other heavy equipment.

-

Additive manufacturing of complex metal components and parts in aerospace, automotive, and tooling industries.

-

Material research for advanced alloys and gradient materials.

-

Precision part repair for non-active metal powders.

Key Features of the Huirui-Laser Automated Laser Cladding System

The Huirui-Laser Automated Laser Cladding System combines elegant industrial design with powerful functionality, offering both 3D printing and surface repair capabilities at an affordable price point. Designed for mid-range and lean manufacturing, it is perfectly suited for batch production, industrial repair, and process optimization.

1. High Integration and Flexibility

The system features a fully integrated architecture with modular laser configuration options. All core components are independently developed and manufactured by Huirui-Laser, ensuring quality and consistency.

It supports multiple process packages and accessories, allowing users to adapt to diverse industrial applications with ease.

2. Servo-Driven Precision Motion System

Equipped with a servo-driven linear module, the system delivers high positioning accuracy, smooth dynamic performance, and compact structure for reliable operation.

The linear motion design maintains a constant spatial relationship between the motion axis and the laser head, ensuring stable load performance and precise processing.

3. Environmentally Friendly and Clean Production

A fully enclosed sheet-metal structure combined with an efficient dust-extraction system minimizes airborne particles, ensuring a clean and safe workspace and protecting both equipment and operators.

4. High-Efficiency Automation

The automatic loading and unloading system significantly enhances the processing efficiency of mining pick components, reducing manual labor intensity and increasing throughput for mass production.

5. Centralized Program Control

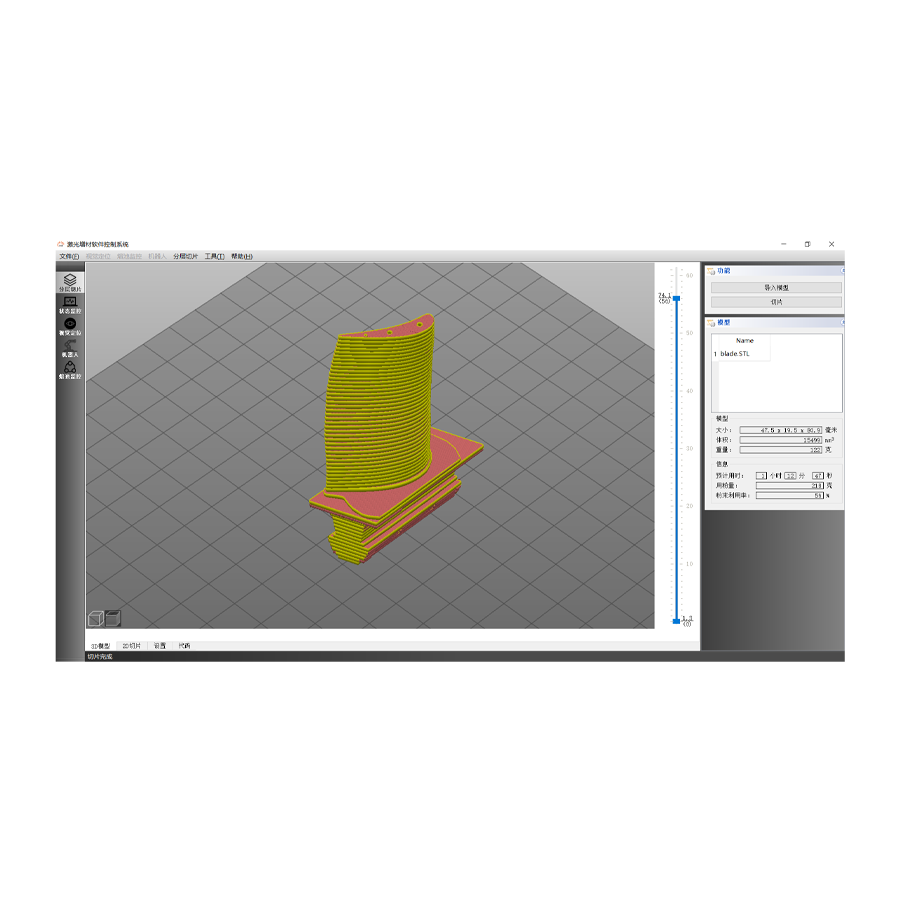

Core components such as the motion control unit, laser source, and powder feeder are managed via centralized software control, providing high system

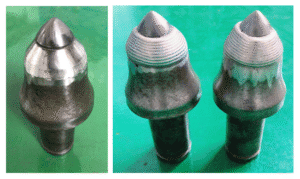

Application Case: Coal Mining Machine Cutter Teeth Laser Cladding

The original hardness of the area to be repaired on the coal mining machine cutter teeth was approximately HRC50. After undergoing the laser cladding treatment, the hardness of the cladding layer was tested and reached HRC55, as shown in the image below.

Key Benefits of Laser Cladding on Coal Mining Cutter Teeth:

-

Enhanced Hardness: The laser cladding process significantly increases the surface hardness of cutter teeth, improving their resistance to wear and extending their lifespan.

-

Superior Durability: With the hardened cladding layer, cutter teeth become more resilient under harsh mining conditions, reducing the frequency of maintenance and replacement.

-

Improved Performance: The higher hardness of the cladding layer enhances the cutting efficiency and overall performance of the coal mining machine.

This application case demonstrates the effectiveness of laser cladding in enhancing the properties and performance of coal mining machine cutter teeth.

| Parameter Category | Specification / Description |

|---|---|

| Equipment Name | Automated Pick Laser Cladding Equipment |

| Laser Power | 3-6 kW |

| Cooling Method | Water Cooling |

| Laser Type | Continuous Fiber Laser |

| Powder Feeding Accuracy | ≤ ±1% |

| Power Stability | < ±2% (2 hours) |

| Two-Axis Travel (XZ) | 600 x 200 mm |

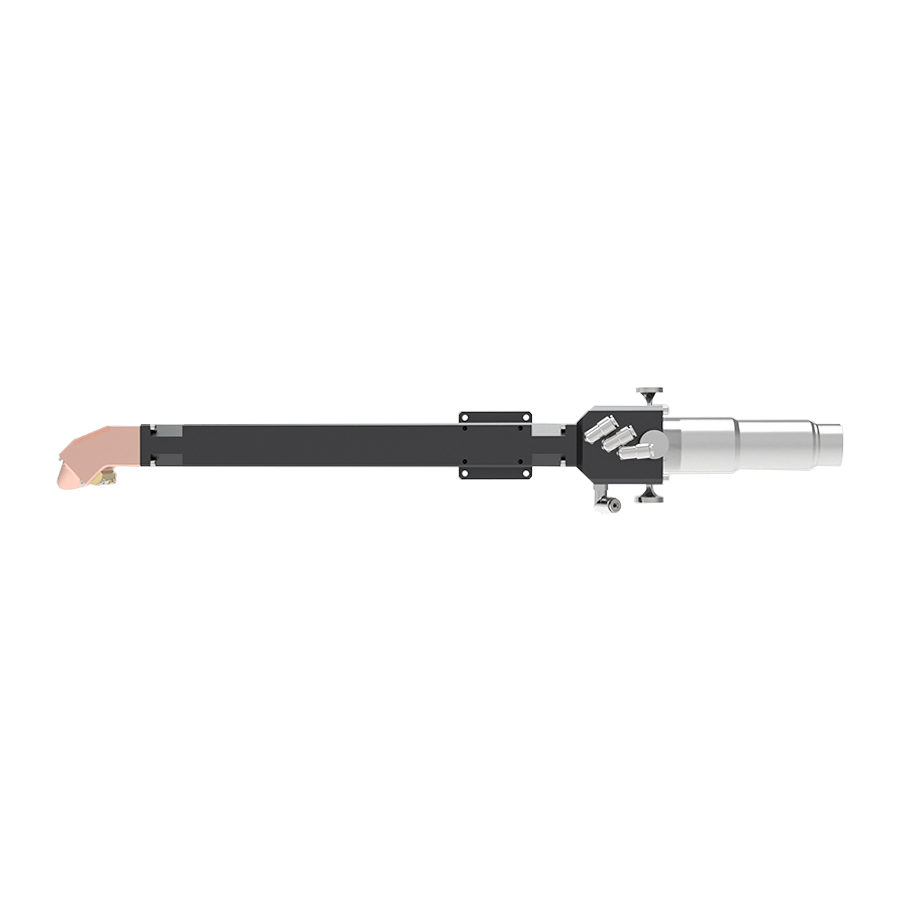

| Optical Path Coaxial Adjustment | X-Y direction precisely adjustable |

| Repetitive Positioning Accuracy | ±0.05 mm |

| Focusing Range | ±3 mm |

| Laser Head | Straight Plate Laser Head |

| Powder Spot Size | 1.0-1.5 mm |

| Powder Feeder | Dual-Cylinder Turntable Pressure Powder Feeder |

| Nozzle | Water-Cooled Reinforced Coaxial Ring Nozzle |

| Powder Feeding Accuracy (repeated) | ≤ ±1% |

| Powder Feed Rate | 1-45 g/min |

| Exterior | Fully Enclosed Sheet Metal |

| Software Configuration | Online Monitoring Software |

Related products

HUIRUI only makes the best products in this industry